Ship propulsion engineering

We’ll be pleased to answer your questions

Ship performance analysis

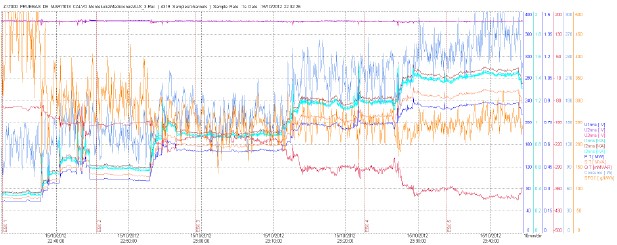

Ship Performance Analysis is a comprehensive engineering process that evaluates how a vessel operates under real-world conditions. At VICUSdt, our ship performance analysis services include detailed energy audits, onboard data collection, hydrodynamic assessments, and regulatory evaluations (EEDI, EEOI, EEXI).

We help identify inefficiencies in propulsion, hull resistance, and auxiliary systems to generate actionable insights for fuel savings, operational reliability, and compliance—delivered through expert naval engineering and data-driven methodology.

Energy audits for ship performance analysis

The goal of energy audits is to identify and analyze how energy is generated and used in the ship to make suggestions for improvements that reduce fuel consumption. Through an energy audit it is possible to quantify exactly the consumption profile of the vessel and the potential for improvement in each field.

Improve your ship performance

The energy balance in a typical ship normally involves a propulsion engine as a primary consumer and secondary consumer, auxiliary groups, as being multiple combinations of drive solutions from the power plant and ancillary equipment (shaft generators, hydraulics, etc.). While the primary consumer is the engine of the ship, we must not forget that this engine uses energy in powering propeller, which in turn, must overcome the resistance of the hull and interact with it and its appendages (nozzle, rudder, etc.). That is why it is essential to focus the audit not only as a collection of data but a detailed analysis which also assess the hydrodynamics of the ship. There are small low-cost actions (such as new designs of bulbs, keels, stern flaps, flaps, nozzles, rudders, etc.) that improve the performance of the vessels significantly. Small investments can lead to big savings over the medium term. There is also command and control technology that can improve the generation and usage of electric power onboard.

Data collection

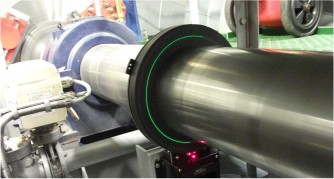

There are several possibilities for data collection on board, which includes records of power consumption, speed, usage profile of the ship, etc.

- Installing permanent or temporary data acquisition.

- Measurement onboard by VICUSdt staff, in several conditions.

- Data collection by the crew.

Advantages for ship owner

Investing in a deeper understanding of your vessel’s operational data can lead to significant cost savings and improved ship performance. Here’s how:

- Immediate Fuel Savings: By analyzing the vessel’s consumption profile, it is possible to detect inefficient operating conditions and eliminate wasteful practices.

- Identification of possible engine problems: such as excessive fuel usage, poor combustion, or mechanical inefficiencies. Early detection allows for proactive maintenance, preventing costly repairs and minimizing downtime

- Characterization of the entire ship hydrodynamics: understanding the full hydrodynamic behavior of the ship—its primary energy consumer—enables better decision-making in optimizing hull performance, propeller efficiency, and overall vessel operation. With data-driven insights, shipowners can enhance fuel economy and operational reliability.

Hydrodynamic Performance and its Impact

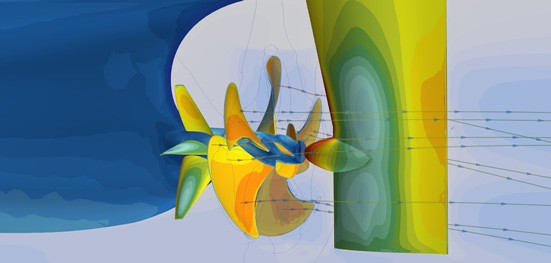

Hydrodynamic performance encompasses the interaction between hull geometry, resistance forces, and propulsion efficiency—core aspects of ship performance analysis. At VICUSdt, accurately determining how a vessel’s hull form, appendages (e.g., bulbs, keel, rudders, flaps), and propeller interact can significantly influence energy consumption and speed. Even minor enhancements can lead to measurable reductions in drag, contributing to better fuel economy and extended operational range.

Modern naval engineering relies on advanced Computational Fluid Dynamics (CFD) simulation to predict pressure and flow fields around the hull, identify wake disturbances in the propeller area, and evaluate resistance under varying conditions like waves or shallow water. CFD enables performance optimization both at concept design and during retrofit, supporting continuous improvements in propulsion integration and energy efficiency. When combined with energy audits and onboard measurements, hydrodynamic insights offer vessel operators a clear path toward performance gains rooted in empirical data and engineering rigor.

EEDI and EEOI verification

Our team of experienced naval architects can carry out EEDI and EEOI assessment and verification. We can take care of all the steps necessary to achieve the required EEDI from concept stage to sea trials. Also ask us for help on existing vessels, the combination of naval architecture capabilities, hydrodynamics experts and sea trial “hands-on” experience is the perfect approach for a successful project.

EEXI compliance services

Calculation of the actual EEXI (Energy Efficiency Existing Ship Index), development and analysis of technical solutions to improve the EEXI for the current ship design (bulbous bow retrofit, Energy saving devices, propeller optimization, etc). Below our four approaches to study the project and providing the best options always looking for the improvement of the vessel.

- Basic EEXIcalculation

- EEXI analysis by CFD

- Express analysis for EEXI improvement

- Development of solutions and implementation

As a result of this type of ship performance analysis you can obtain the following results:

- Total fuel / energy consumption per machine over a certain period.

- Average and peak efficiency of different ship systems.

- Transport efficiency and EEDI analysis.

- Ship performance in different operational scenarios and different technologies.