Ship propulsion engineering

Can we help you?

We’ll be pleased to answer your questions

CFD Aerodynamics

CFD airflow simulation in the ship

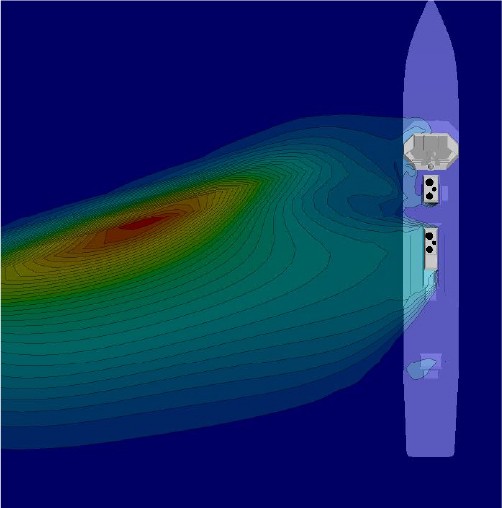

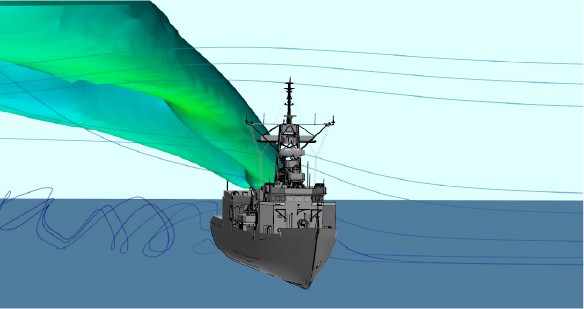

Aerodynamic CFD simulation allows us to analyze the behavior of the air over the vessel, as well as exhaust or ventilation gases in all types of ducts in a quick and reliable way.

Our CFD airflow simulation allows a precise calculation of aerodynamic forces and moments over the hull and superstructure of the ship.

When is it advisable to do a CFD aerodynamics analysis?

- Ship resistance. It can make a significant contribution on high speed boats.

- Docking maneuvers and sizing of tunnel thrusters.

- Dynamic positioning.

- Anchoring and mooring calculations. Useful when sizing mooring lines for instance.

Exhaust gases and helideck

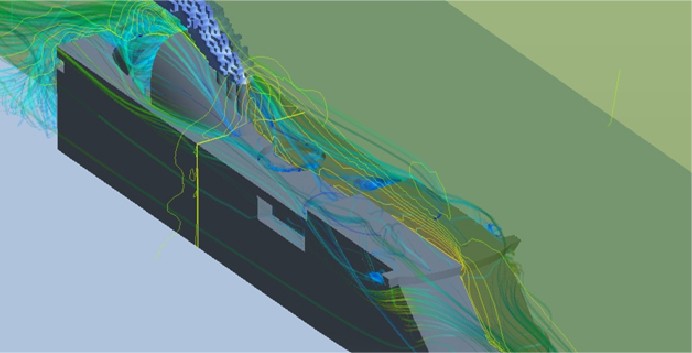

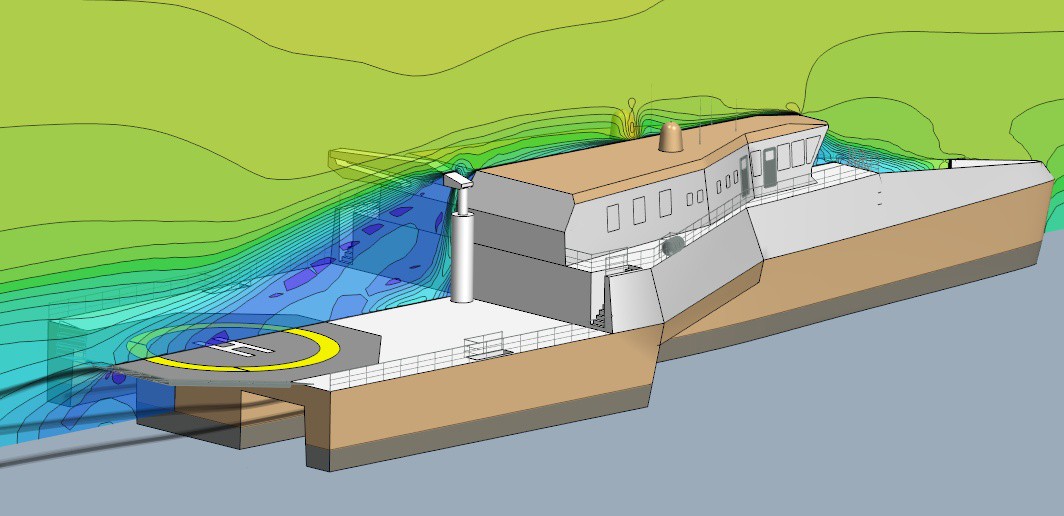

Calculating the trajectories and temperatures of the exhaust gas flow from the engines and how it interacts with other areas of the ship such as antennas, sensors, air intakes and helidecks by monitoring the evolution of the thermal plume.

Regarding the CFD calculation on helidecks, we apply the CAP 437, NORSOK C-004, HSAC RP or Brazil NORMAM 27 regulations in order to minimize the risk associated with the effect of wind turbulence and to ensure safe helicopter operations.

CFD Aerodynamics for Helidecks analysis

Helicopter landing in vessel decks is a critical operation.

Wind heading and intensity affect directly helicopter stability because strong gusts of winds produce so much turbulence in helidecks that it is impossible to operate.

Moreover, hot gases from ship exhaust funnels are also an important factor. If thermal rise between enviromental temperature and gases temperature is high, the helicopter will experience lift changes that can cause high instabilities, putting the operation at risk.

CDF aerodynamics simulations are very useful tool to develop these studies. They allow to reproduce the turbulence and temperature tendency that will experience the air close to the helideck. Air flow instabilities are produced by superstructure and thermal flow from exhaust funnels or by other thermal sources. CFD allows to study alternatives to mitigate both thermal and turbulence effect in landing zone.

Safer helicopter landings

Achieve comfort with CFD aerodynamics simulations

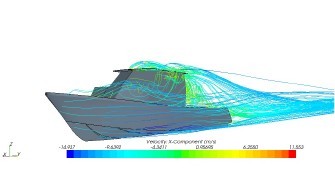

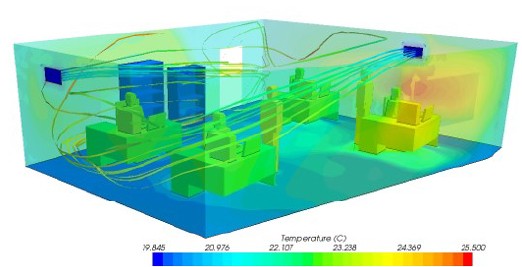

The degree of aerodynamic comfort on balconies and terraces is verified through CFD simulations at the different speeds and directions of the ship, checking different variables such as turbulence, concentrations and odors of the exhaust gases at different points of the ship, as well as the increase in temperatures produced.

Comfort in crew or passenger accommodation areas is also checked by evaluating air velocity, temperatures and gradients, among other parameters.

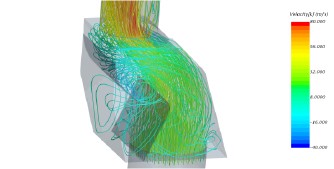

Ventilation in engine room, exhaust and HVAC pressure drop

Pressure drop in exhaust and ventilation ducts, as well as air distribution in engine room and other spaces including smoke dispersion on the garage of a RoRo for instance. We have experience modeling scrubbers, water separators, silencers and other components of exhaust lines. In addition, we can perform the coupled thermo-mechanical calculation CFD-FEM to evaluate stresses in the elastic support of the exhaust.