Customer: ALTAMAR

Related services: FEM SIMULATION

Scope of work:

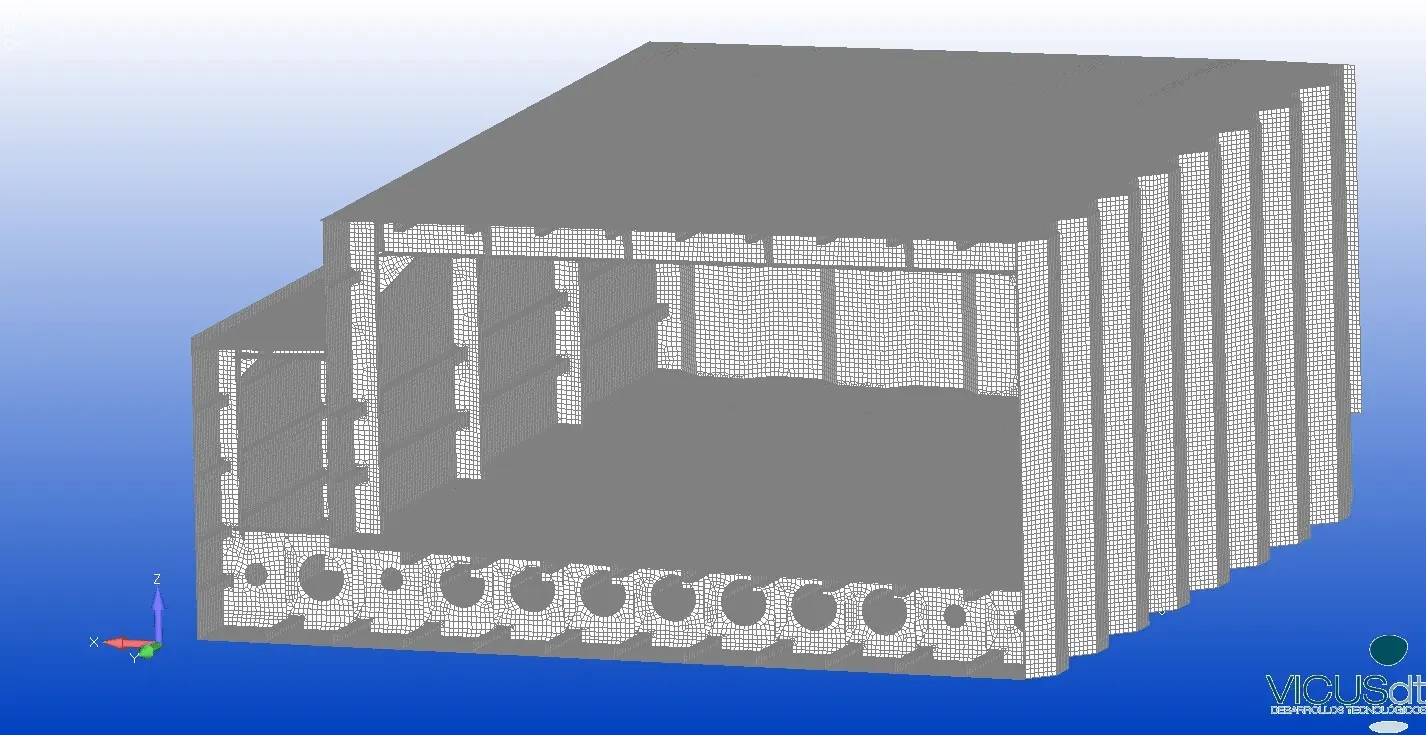

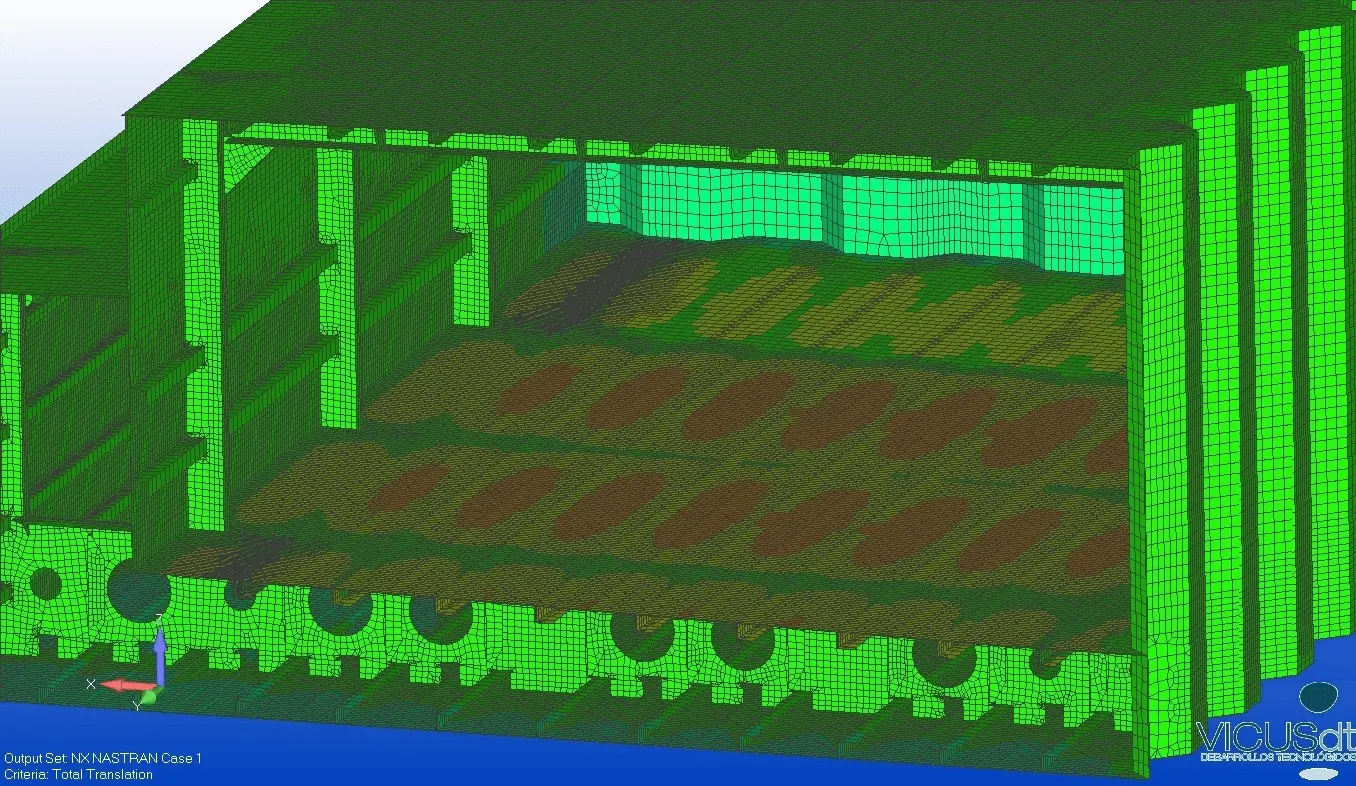

- Generate 5 tanks geometry in 3D using NX program based on the data provided by the customer.

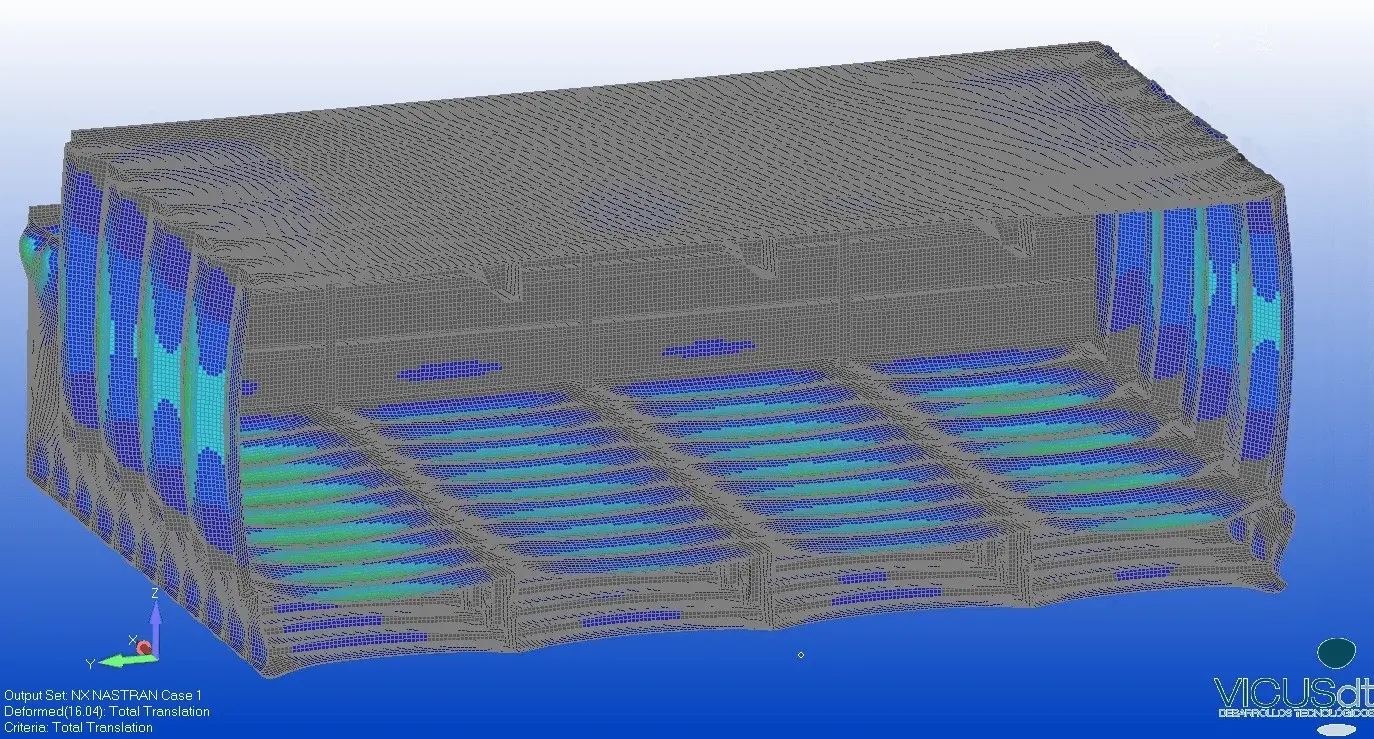

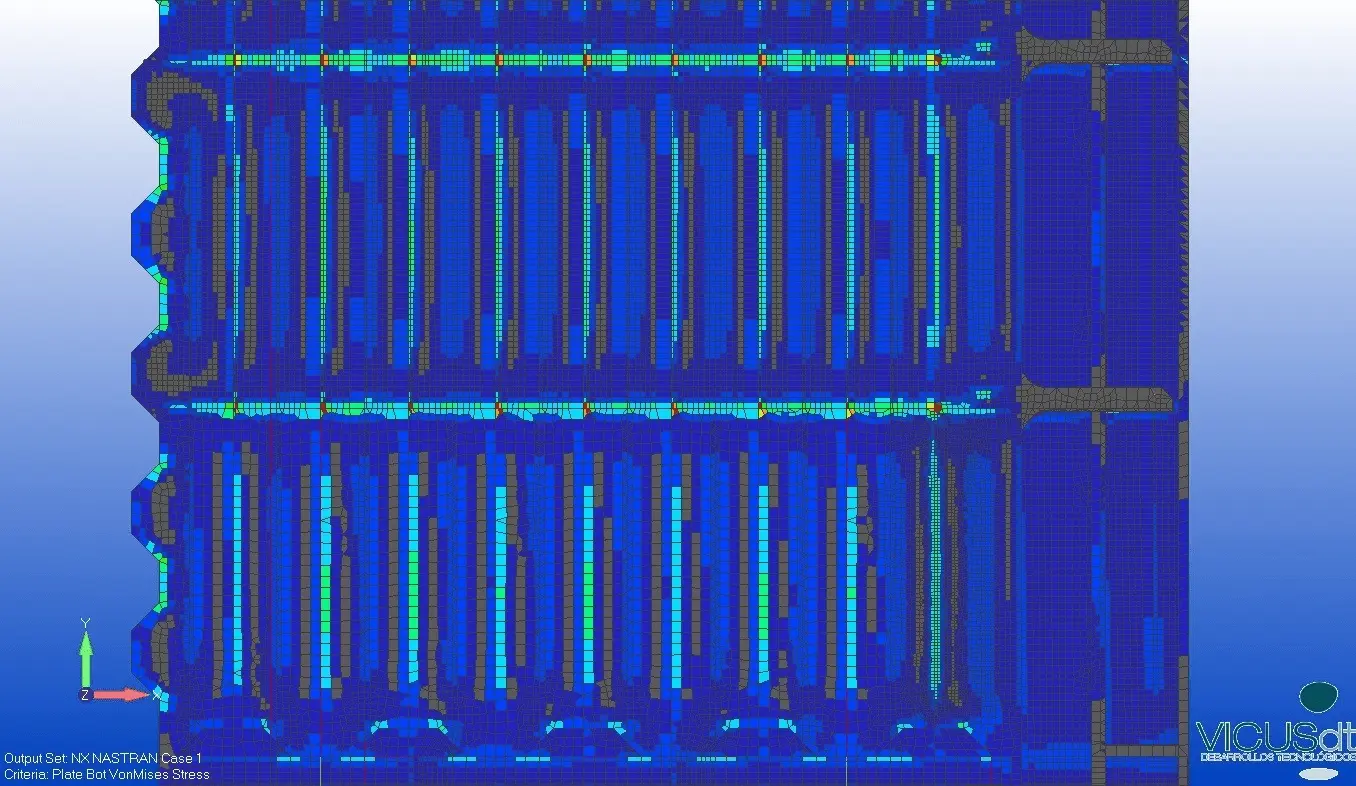

- Calculation of the Von Mises stresses and translations for the worst case load (tanks 2, 3 and 4 loaded) with FEMAP program.

- Evaluation of results according to material characteristics.

- Modification proposals in cases where the results exceed the yield stress of the material.

- Generate the changes proposed and agreed with the customer in 3D. Two possible alternatives were analyzed.

- Calculate the stresses and translations for both alternatives in the worst case load.

- Analyze the results and draw conclusions.

Results:

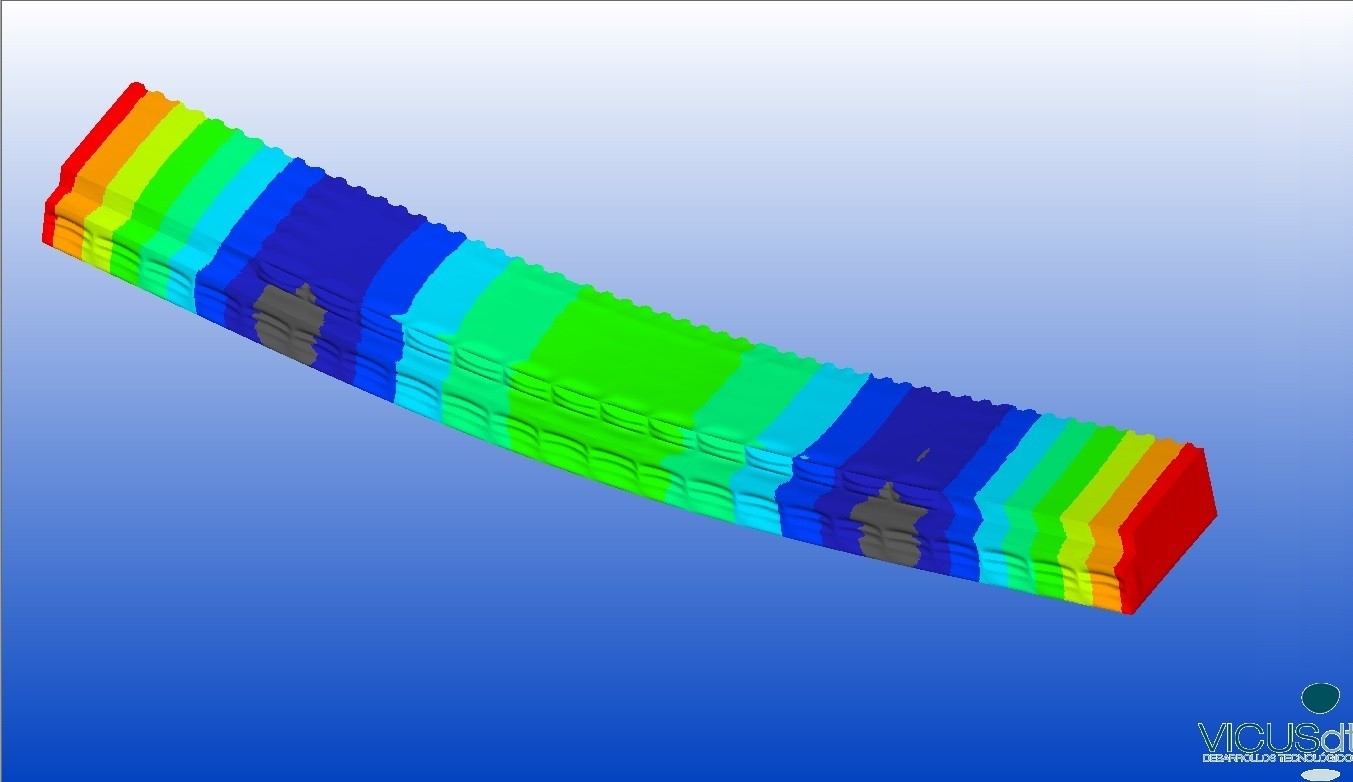

As a result of this project, the evaluation of stresses and translations in the double bottom showed initial results were close to the yield stress. The deformations were high in the double bottom.

After this first evaluation were proposed some changes in the structure to improve this condition. Bottom longitudinals, girders, beams and two lengths were added.

The suggested modifications were taken into account and implemented to achieve an adequate level of tensions. It is also concluded, in view of the permanent deformation observed on the barges, that in addition to the load, the process of filling the tanks and welding after the launch, other factors must be involved to justify the appreciated deformations on the ships. Such as: blows against the hull, poor welding, …