This vessel retrofit project for the general cargo ships Marit and Myrte demonstrates how targeted propulsion upgrades can significantly enhance fuel performance. By applying advanced CFD analysis and integrating customised energy-saving devices, VICUSdt achieved measurable improvements in cargo ship fuel efficiency, reducing consumption and emissions

The optimized design of the propulsion system by Computational Fluid Dynamics (CFD) has allowed for an improvement in efficiency over 4%, facilitating a quick return of investment for Sam Shipping.

The upgrade was part of a broader cargo ship propulsion retrofit strategy aimed at reducing fuel consumption and increasing ROI through energy-efficient technologies.

Sam Shipping, shipowner based in Netherlands, has relied on VICUSdt hydrodynamic engineering services to improve the performance of the twin general cargo vessels Marut & Myrte.

How Vessel Retrofit Enhances Marine Energy Efficiency

Retrofitting is one of the most effective strategies to improve marine energy efficiency and reduce operational costs. Instead of replacing entire propulsion systems, targeted retrofits allow shipowners to modernise existing vessels and comply with current IMO efficiency standards. VICUSdt combines propulsion engineering expertise and CFD simulations to optimise hydrodynamic performance and minimise drag.

CFD Analysis to Optimice Cargo Ship Propulsion

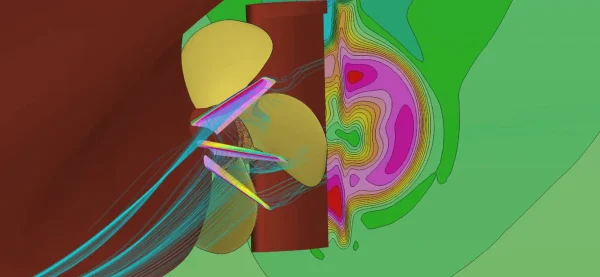

Each vessel retrofit begins with comprehensive CFD (Computational Fluid Dynamics) simulations to evaluate propulsion performance. For Marit and Myrte, our team analysed hull–propeller interaction, wake field, and thrust potential to identify energy losses. These insights guided the retrofit design, ensuring measurable gains in cargo ship propulsion efficiency and reduced fuel consumption.

The Express Analysis conducted by VICUSdt has been crucial in selecting the most suitable technologies to reduce fuel consumption in both vessels as part of their retrofitting project. The Express Analysis calculates the potential savings of consumption reduction technologies such as bulbous bow, pre-swirl stator (PSS), etc. by means of CFD studies.

Additionally, it estimates the investment required for their installation. Based on these values, the Return of Investment (ROI) is derived as a key parameter for selecting the actions to be carried out within the retrofit project.

Among the evaluated technologies, Sam Shipping selected the pre-swirl stator (PSS). The PSS is an Energy Saving Device that is installed ahead of the propeller to optimize the water flow, thus improving the propulsion system’s performance.

Detail engineering, manufacturing and pre-swirl stator implementation

Following the selection, Sam Shipping entrusted VICUSdt with the detailed design, manufacturing of installation of the PSS on both twin ships.

The retrofit included detailed engineering, manufacturing, and on-site implementation of the PSS units. Each component was tailored to the vessel’s propulsion layout, ensuring perfect integration with the existing system. By combining precision manufacturing and CFD-backed design, VICUSdt maximised performance and ensured compliance with class society standards.

VICUSdt designed and optimized the PSS by applying CFD analysis methodologies. Also, the engineering firm managed the PSS production with local suppliers and facilitated the devices’ class approval. Afterwardf, last October, they provided technical assistance during the installation of the PSS on Marit MV at Remontowa shipyard in Poland. The project team engineers will travel to install the second PSS on its twin ship, Myrte in the coming months.

Key Results of the Retrofit Project Implementation

Following installation and sea trials, both cargo ships achieved, thanks to the optimized design of the propulsion system (propeller, PSS and rudder) using CFD simulation, a 4.1% improvement in propulsive efficiency and a measurable reduction in fuel consumption. CFD validation confirmed improved wake alignment, reduced resistance, and optimised thrust distribution. The retrofit not only enhanced performance but also extended the vessels’ operational lifespan and environmental compliance. This ensures a quick Return of Investment of the retrofit project, within a timeframe of less than two years.

Why Vessel Retrofit Is a Smart Investment for Shipowners

A vessel retrofit is one of the most cost-effective strategies for shipowners seeking to reduce fuel consumption and emissions. Projects like Marit & Myrte show that efficiency gains of just a few percent can translate into significant annual savings. With rising fuel prices and environmental targets, retrofit solutions deliver immediate and long-term value.