The study was carried out for MINMARINE Shipmanagement GmbH & Co. KG, a German ship owner and manager. VICUSdt applied hydrodynamic study and propulsive improvements to the Golden Grains vessel. These measures reduced operating costs significantly. The investment was recovered in record time.

The bulk carrier fuel savings achieved by MV Golden Grains illustrate VICUSdt’s Express Analysis impact. Within a few months post-retrofit, the vessel recorded a 3% net fuel saving, with options studied yielding up to 10% fuel reduction. The scope of work included data collection and calculation scenario analysis for the ship’s hydrodynamics and propulsion technologies.

Measures included trim optimisation (no cost), installation of a finned propeller hood or rudder bulb (≈ 2–5%), and an air lubrication system (≈ ±10%). The short docking window and fast payback impressed the ship’s owner, proving that targeted hydrodynamic enhancements can deliver immediate ROI and lower operating emissions.

The short docking window and fast payback impressed the ship’s owner, proving that targeted hydrodynamic enhancements can deliver immediate ROI and lower operating emissions.

Key interventions & savings breakdown

Following the Express Analysis, MV Golden Grains implemented:

- Trim optimisation: slight shift forward trim reduced hull resistance by ~8–10% with no CAPEX required

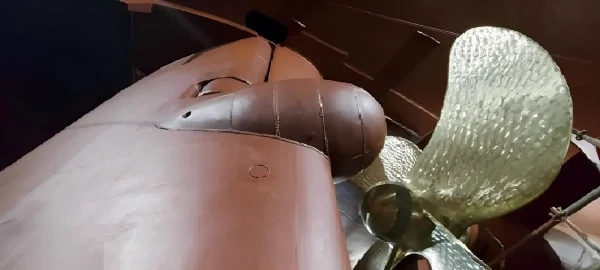

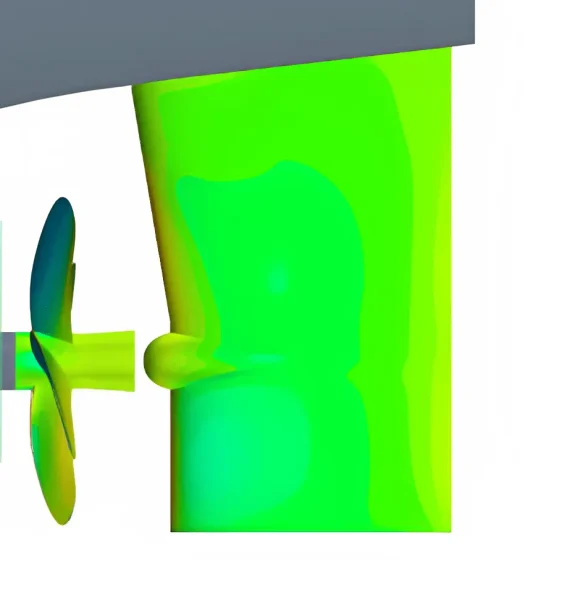

- Wake-adapted propulsive appendages: installing a rudder bulb (WakeBulb) recovered propeller rotational energy, resulting in ~2–5% fuel savings.

- Air lubrication system: injection of air under the hull cut frictional resistance, offering up to ±10% savings depending on vessel loading and fuel type. The retrofit took just 8–14 days and paid back within months.

Together, these measures produced tangible savings—with a 3% verified reduction on sea trials and higher theoretical potential with progressive enhancements.

ROI & operational value for shipowners

The Golden Grains project demonstrates how bulk carrier fuel savings can translate into rapid return on investment, even in highly competitive dry bulk markets. Fuel makes up a significant portion of operational cost, so even marginal gains directly improve profitability.

- Immediate financial payback: minimal-cost measures delivered ROI in months, while moderate investments (bulb, lubrication) enhance long-term returns.

- Regulatory readiness: improved fuel efficiency supports compliance with evolving IMO standards (EEXI, CII), enhancing vessel valuation and charter competitiveness.

- Operational flexibility: short installation schedules enabled retrofit during routine dockings, avoiding extended downtime.

- Environmental benefit: reduced CO₂ emissions strengthen ESG credentials—critical in chartering decisions and financing.

Vessel operators and shipowners considering similar bulkships can replicate this success through VICUSdt’s structured Express Analysis: fast, cost-effective, and results-driven.

The fabrication of the rudder bulb, as well as its installation, was carried out by the shipyard itself, where the planned docking was carried out following the plans and instructions of VICUSdt. Once the work was completed and verified by the classification society, the sea trials were carried out again where the improvements that this Spanish company had promised were confirmed.

The Golden Grains vessel is a 181-meter-long bulk carrier with a deadweight of 37,597 tons. By applying the proposals of the study carried out by VICUSdt, the return on investment has been achieved in a few months, providing a saving of 3%.