During the Shipbuilding & Ship Management (SBSM) online event organized by Tech 4.0, Adrián Sarasquete, Managing Director at VICUSdt, presented a practical session on how Computational Fluid Dynamics (CFD) is transforming fleet performance optimization across the shipping industry.

Rather than focusing on theoretical modeling, the session explored how CFD supports real-world engineering decisions, from hull and propeller optimization to Energy Saving Devices (ESDs) and wind-assisted propulsion systems, helping shipowners reduce fuel consumption, minimize retrofit risk, and achieve measurable efficiency gains.

Contenidos

- 1 Why CFD Matters at Fleet Level

- 2 A Real Case: When an Energy Saving Device Delivered No Gain

- 3 Hull Optimization Through CFD

- 4 Accounting for Real Sea States

- 5 Propeller and Propulsion System Optimization

- 6 Energy Saving Devices: Small Margins, High Sensitivity

- 7 Aerodynamics and Wind-Assisted Propulsion

- 8 Data Quality: The Foundation of Reliable CFD

- 9 CFD Is Not a Black Box

- 10 From Simulation to Operational Impact

Why CFD Matters at Fleet Level

CFD is a mature engineering technology that has been used in naval architecture and aerospace design for decades. Today, it plays a critical role in fleet-level decision-making by enabling full-scale, physics-based simulation of real operating conditions.

One of the key takeaways from the session was that solutions cannot be generalized pc across vessels, even within sister ship series. Each hull form, propulsion system, and operational profile requires its own hydrodynamic assessment — and CFD provides the most accurate and cost-effective way to perform this analysis.

Beyond optimization, CFD also provides independent validation, allowing shipowners to verify vendor claims and reduce investment uncertainty before committing to retrofits or newbuild modifications.

A Real Case: When an Energy Saving Device Delivered No Gain

The session opened with a real operational example involving a 180,000 DWT Capesize bulker that had installed an Energy Saving Device expected to deliver around 10% fuel savings.

After conducting CFD-based resistance and self-propulsion studies, the result was unexpected:

The device delivered virtually no performance improvement.

While it fortunately did not increase resistance, the vessel owner had invested several hundred thousand dollars with no measurable return. The root cause was not the technology itself, but the lack of vessel-specific hydrodynamic analysis prior to installation — highlighting the importance of CFD as a risk mitigation tool.

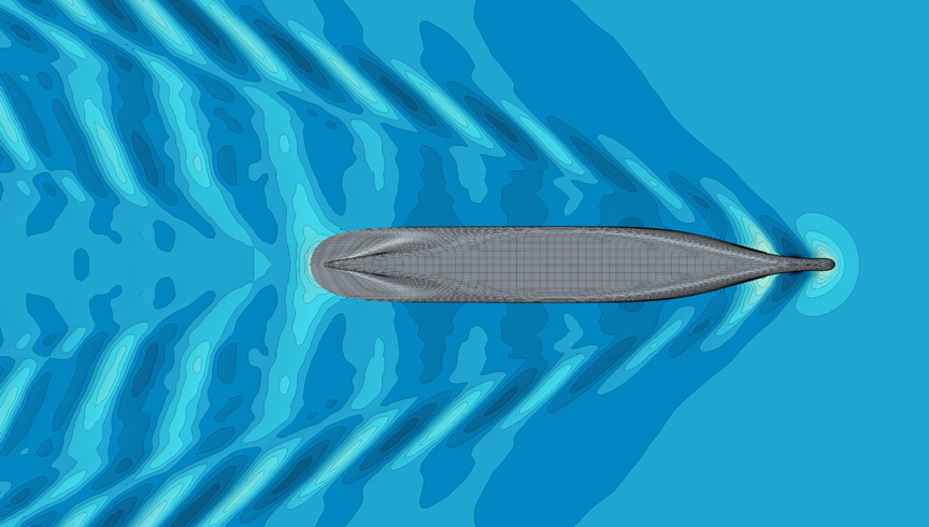

Hull Optimization Through CFD

Hull resistance analysis was one of the earliest applications of CFD in ship design and remains one of its most valuable.

CFD enables:

- Accurate prediction of wave-making resistance

- Assessment of trim and draft sensitivity

- Optimization of appendage geometry

- Evaluation of frictional resistance and air lubrication concepts

- Detailed wake field analysis to support propeller design

By simulating hundreds of hull variants across multiple operating conditions, engineers can identify the most efficient configurations for real service profiles — not just theoretical design points.

Accounting for Real Sea States

Ships operate in dynamic environments, and sea state has a significant impact on resistance, propulsion loading, and fuel consumption.

CFD enables simulations in waves, allowing:

- Prediction of added resistance in realistic sea conditions

- Evaluation of propeller performance under fluctuating inflow

- Optimization of offshore vessel configurations exposed to complex wave effects

This ensures vessels are optimized for actual operating conditions, not only calm-water performance.

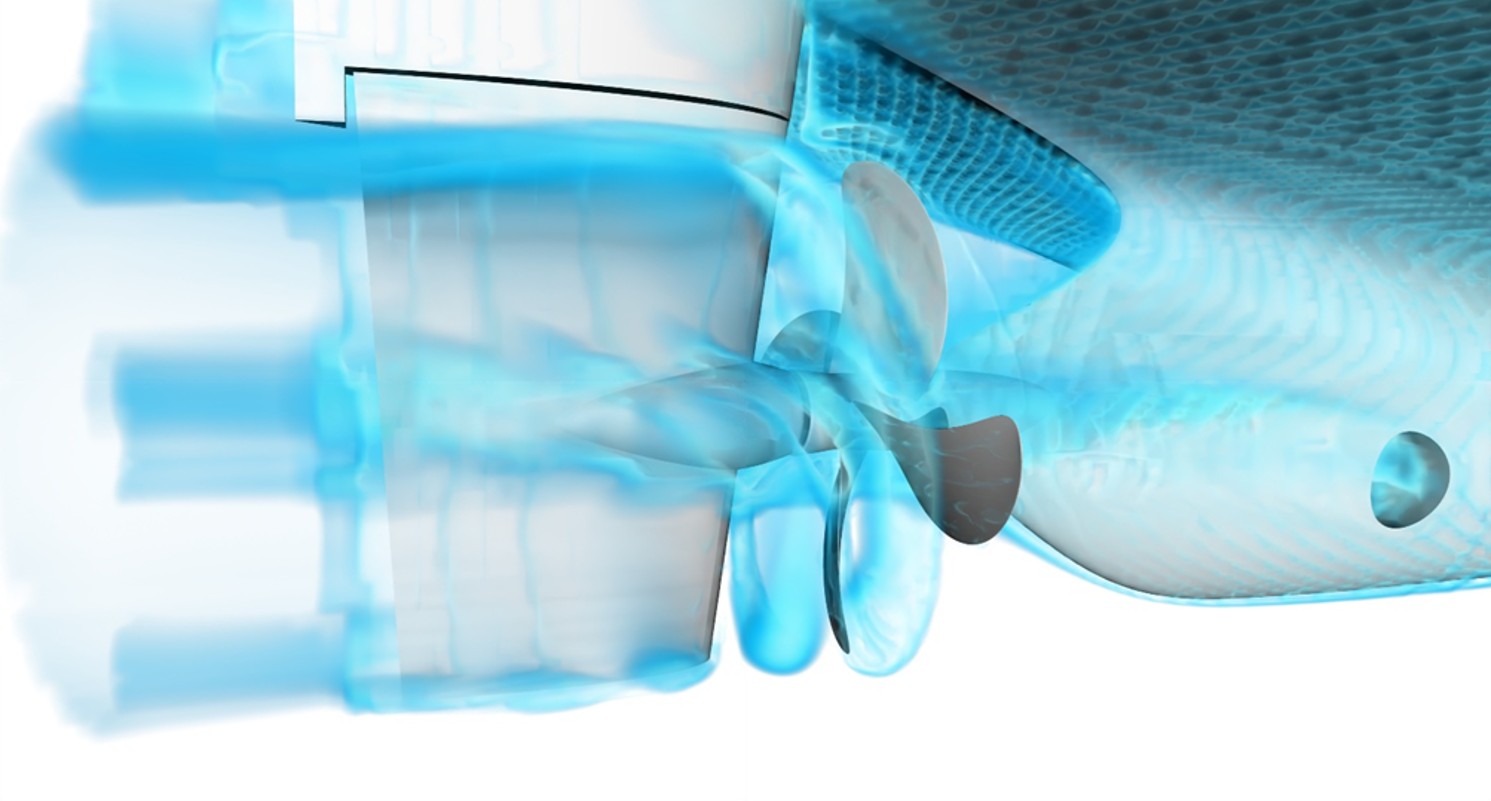

Propeller and Propulsion System Optimization

Modern CFD allows fully coupled simulations of:

- Hull

- Propeller

- Rudder

- Appendages

- Wake field

This integrated approach delivers highly accurate thrust and torque predictions and enables engineers to optimize the entire propulsion system as a single unit rather than isolated components.

Additional benefits include:

- Improved cavitation prediction and mitigation

- Reduction of pressure pulses and vibration risk

- Better maneuverability and course-keeping

- Hydro-structural coupling for blade strength and fatigue optimization

Energy Saving Devices: Small Margins, High Sensitivity

Energy Saving Devices typically offer realistic efficiency gains of 3–5%, but achieving these gains requires extremely precise hydrodynamic optimization.

CFD plays a critical role in:

- Selecting the most suitable ESD technology

- Optimizing geometry for operational profiles

- Evaluating cavitation and vibration risks

- Understanding interactions between hull wake, propeller inflow, and appendages

Without proper CFD validation, ESD retrofits risk delivering limited or even negative performance results.

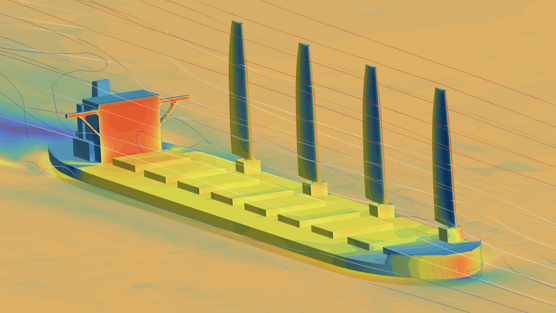

Aerodynamics and Wind-Assisted Propulsion

With the rapid adoption of wind-assisted propulsion systems, aerodynamic CFD has become increasingly relevant. However, its greatest value lies in understanding the interaction between aerodynamic forces and underwater hydrodynamics.

Wind propulsion introduces new forces and moments that affect:

- Propeller loading

- Rudder angles and steering corrections

- Course-keeping efficiency

- Cavitation behavior

CFD enables engineers to evaluate these coupled effects and ensure aerodynamic gains are not offset by underwater efficiency losses.

Data Quality: The Foundation of Reliable CFD

CFD results depend directly on the quality of input data. High-fidelity studies require:

- Accurate vessel geometry

- Reliable operational profiles

- Knowledge of hull and propeller condition

- Realistic roughness modeling

Rather than over-modeling minor details, CFD studies must focus on accurately representing the physical reality of the vessel.

CFD Is Not a Black Box

A recurring message throughout the session was that CFD must not be treated as a black box tool.

Every result should:

- Be physically explainable

- Be consistent with hydrodynamic principles

- Be defensible with engineering reasoning

High performance claims without physical justification should always be treated with caution.

From Simulation to Operational Impact

With over 1,500 propulsion engineering projects completed, VICUSdt applies CFD as a performance engineering tool, not simply as a simulation exercise.

When used correctly, CFD supports:

- Safer retrofit investments

- Reduced fuel consumption

- Improved propulsion reliability

- Better regulatory compliance

- Long-term operational efficiency

CFD is not about producing simulations — it is about delivering measurable performance outcomes.

Don’t want to miss our news?!

Follow us on LinkedIn to stay updated on upcoming events, insights, and maritime efficiency solutions.