Optimization of counter rotating propellers by CFD

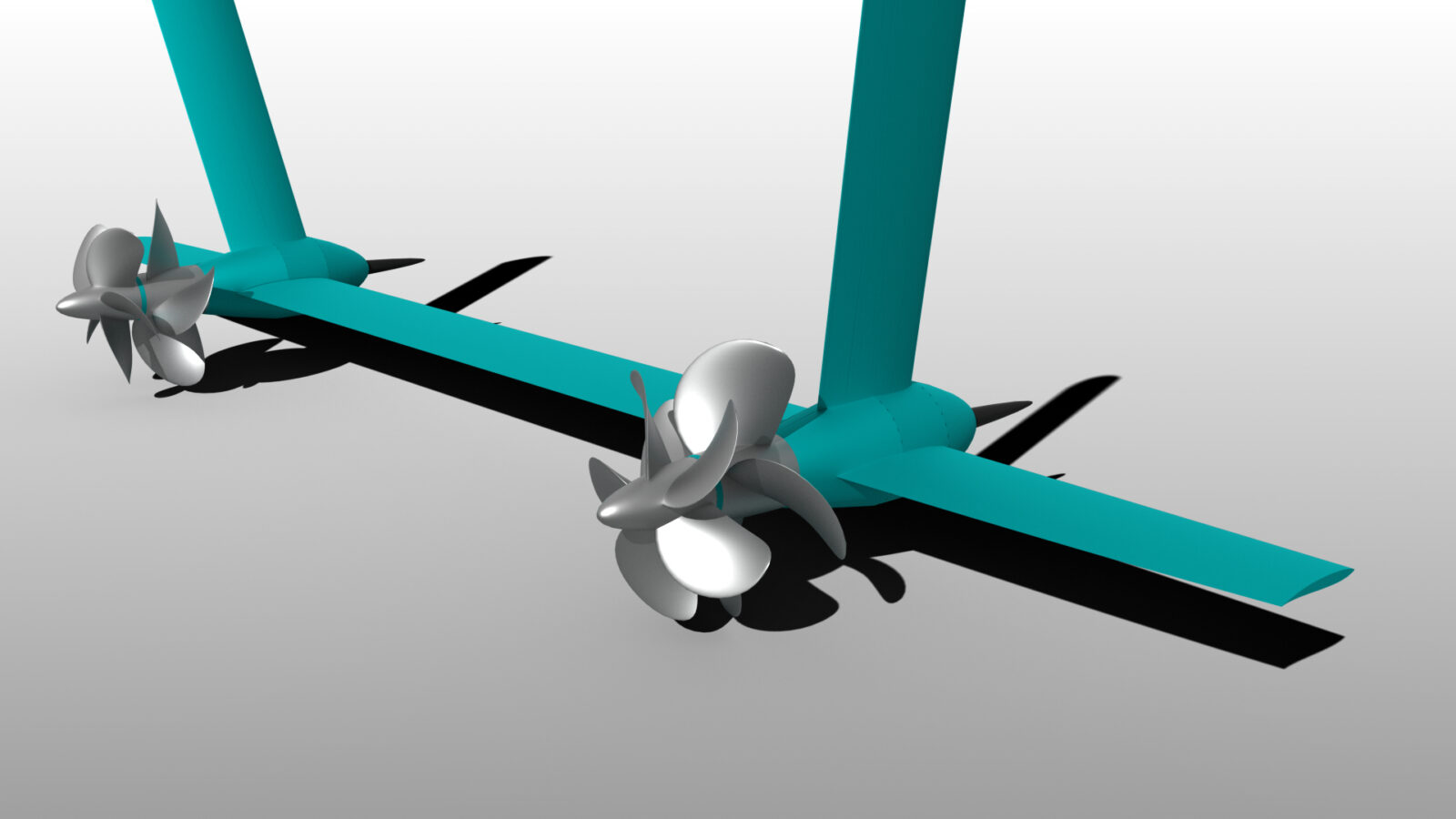

CRP consist of two propellers mounted on the same shaft, rotating in opposite directions. This configuration provides numerous advantages compared to single propeller systems. The two propellers operate in a contra-rotating manner, where the downstream propeller partially recovers the rotational energy lost by the upstream propeller, resulting in an increase overall propulsive efficiency. The interaction between the propellers also reduces unbalanced torque and rotational forces, contributing to improve stability and manoeuvrability.

Some performance benefits of CRP in hydrofoil vessels:

- Increased Thrust and Efficiency: The contra-rotating configuration minimizes rotational losses and optimizes the conversion of engine power into forward motion, enhancing overall propulsion efficiency. This results in higher speeds and improved fuel economy, enabling hydrofoil vessels to cover longer distances without compromising performance.

- Enhanced Manoeuvrability: The contra-rotating arrangement reduces the rotational moment, making easier to control the vessel’s yaw, pitch, and roll. This improved manoeuvrability allows a more precise navigation, quick course corrections, and efficient docking even in challenging environmental conditions.

- Stability and Reduced Vibrations: The CRP system contributes to increased stability by minimizing the propeller-induced yaw and roll moments. The opposing rotation of the propellers counteracts the rotational forces, resulting in reduced vessel vibrations and enhanced ride comfort for passengers and crew.

CHALLENGES FOR CRP DESIGN AND IMPLEMENTATION:

While CRP offer numerous advantages, their implementation requires careful engineering and consideration of certain points, as follows:

- The design and construction of CRP systems are more complex and expensive compared to single propeller arrangements. The synchronization of the two propellers, ensuring balanced thrust distribution, and managing the contra-rotating forces demand advanced engineering expertise and precision manufacturing.

- Regular inspections, lubrication, and alignment checks are crucial to ensure optimal performance and prevent premature wear. Access to both propellers can be challenging, requiring dedicated maintenance procedures and skilled personnel.

While the implementation of counter-rotating propellers may pose challenges, the overall advantages outweigh the complexities. Continued research and advances in CRP technology will further enhance the performance and efficiency of hydrofoil vessels, enabling faster and more reliable maritime transport.

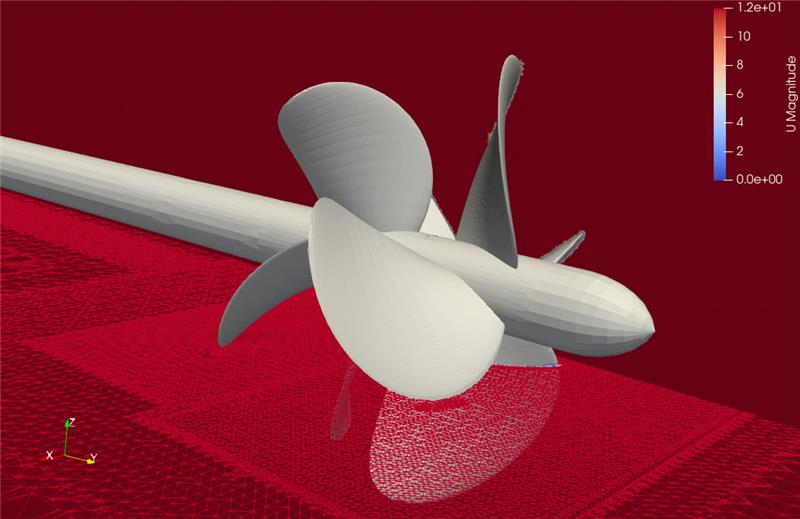

The use of Computational Fluid Dynamics (CFD) tools allow an efficient design of these type of propellers in a very efficient way, allowing the designer to take advantage of all the potential by capturing the interaction flow in a very accurate way. VICUSdt regularly carry out design and optimization of counter rotating propellers by CFD, providing an optimized design for every application of this interesting solution.