Ship propulsion engineering

Special cfd simulations

At VICUSdt, our cfd simulations offer advanced virtual modeling of fluid behavior around marine vessels and their components—without the need for physical testing.

More than propulsion systems experts

And we are not only experts in ship propulsion systems, we can analyze other types of fluid dynamic problems in ships.

What other fluid dynamic problems do we deal with at Vicusdt?

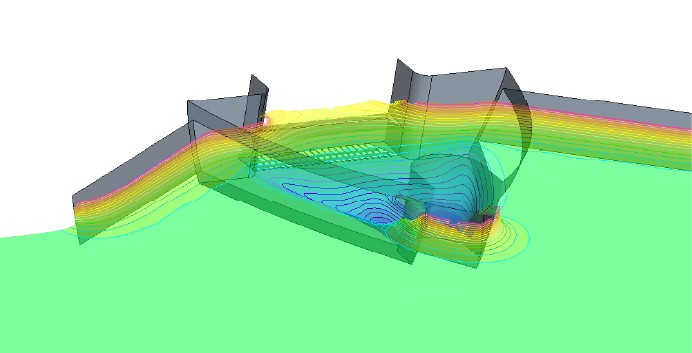

- Sea chests: Through CFD simulations, VICUSdt can evaluate flow patterns entering the sea chest to prevent vortex formation, air ingestion, and sediment accumulation. Proper flow management ensures consistent water supply, minimizes clogging risk, and improves the performance of downstream equipment such as pumps and filters.

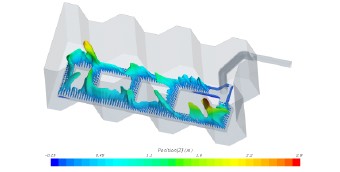

- Box coolers: We assess water velocity distribution around the cooler surfaces, ensuring optimal heat transfer and avoiding stagnant zones that may promote marine growth. These studies help optimize placement and flow channels to enhance cooling efficiency and extend maintenance intervals.

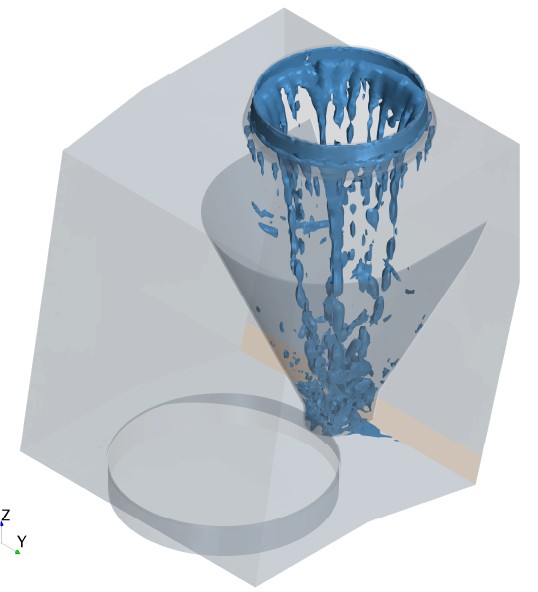

- Scrubber water cleaning: VICUSdt applies CFD to model fluid movement inside cleaning units, improving particle separation, avoiding short-circuiting flows, and ensuring compliance with environmental discharge standards.

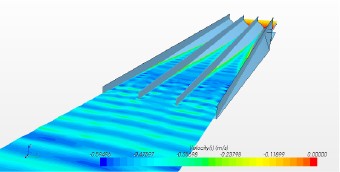

- Side discharges: we predict discharge plume trajectories, velocity decay, and potential re-ingestion into intakes. This analysis helps minimize environmental impact and avoid operational inefficiencies.

- Oil recovery: VICUSdt can model separation chambers, skimmer performance, and settling behavior to improve recovery rates and comply with pollution prevention regulations.

- RSW tank flow, etc.