Propulsion equipment

We’ll be pleased to answer your questions

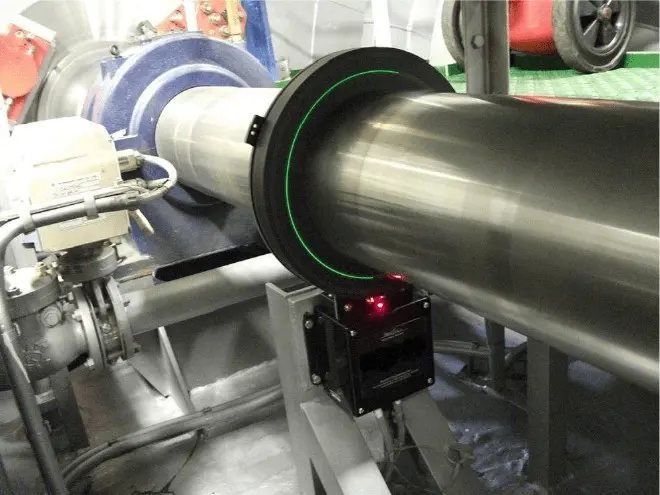

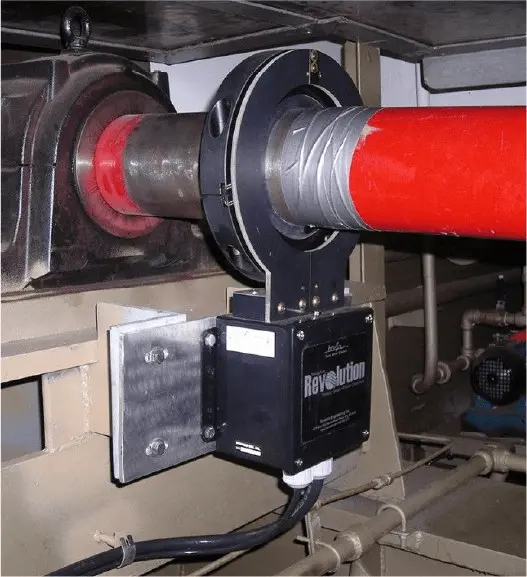

Torque meters

Binsfeld Engineering official distributor

The monitoring of the real power delivered to the propeller is a fundamental aspect for the control and improvement of the propulsive efficiency of the ship. As an official distributor of Binsfeld Engineering, we have reliable solutions for non-contact power and torque monitoring on drive shafts on ships (and other machinery)

Efficiency and consumption

The available product range includes solutions for permanent monitoring or portable systems for use in sea trials. The TT Revolution and TPM-2 fixed systems can be integrated into ship performance monitoring systems in a very simple way for continuous operation, while the TT10K system allows quick installation for temporary measurements.

Reliable and accurate data

The system is based on a microprocessor that features 14-bit signal processing to provide reliable and accurate data in real time during actual operation of the ship’s propulsion system.

- Easy installation, no need to disassemble the shaft

- Reliable operation

- Shafts up to 1.0 m in diameter

- Simple calibration

- Digital data transmitter

- Robust construction

- Intelligent system

- Technical Support

Highlighted

Permanent monitoring of energy efficiency:

- Reduce downtime by knowing when motor, propeller, gearbox or bearing performance degrades.

- Initiate preventative maintenance or replace worn components only when necessary.

It allows to optimize fuel consumption and reduce emissions:

- Combine mechanical power. measurement with fuel flow meters, combustion monitoring and ship speed to monitor fuel consumption and improve efficiency.

- Meet emissions requirements by optimizing efficiency.

TT10K portable torque meter as a fundamental tool for sea trials and diagnostics:

- Diagnose propulsion problems.

- Find out why helmet efficiency has degraded (helmet fouling).

- Determine the root cause of excessive torsional vibration in the propeller shaft.