We’ll be pleased to answer your questions

Propeller Nozzles Design

We design and supply all types of propeller nozzles for ships.

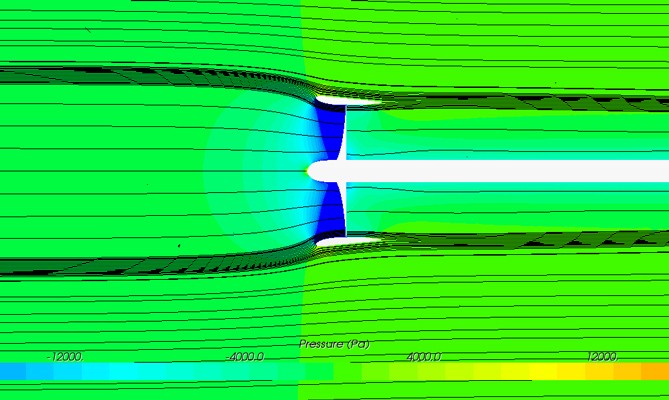

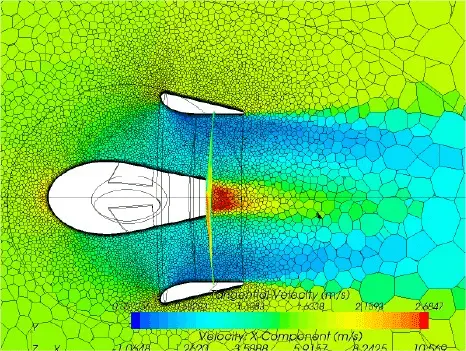

A propeller nozzle is a specially designed duct that surrounds the propeller to optimize water flow, boost towpull, and improve propulsion efficiency. Our nozzle design process uses CFD tools to balance hydrodynamic performance with structural integrity, making it ideal for both retrofitting and new builds.

The propeller nozzle is designed using CFD to work in harmony with the propeller and hull, delivering higher thrust and improved maneuverability.

Custom propeller nozzles to improve towpull

Choosing the right profile for your nozzle needs a dedicated analysis that VICUSdt can provide as a key-turn supplier. Our services include on-site measurement, integration drawings with the ship’s structure, FEM and CFD calculations as well as complete retrofitting projects from the feasibility study to sea trials.

Custom propeller nozzle design is especially relevant for tugboats, fishing vessels, and other ships operating at low speeds where maximizing thrust is essential. Our team provides recommendations on nozzle type, dimensions, and integration with the existing propulsion system.

The result is a fully customized propeller nozzle for ships that improves propulsion efficiency and reduces energy losses. This propelling nozzle solution is ideal for vessels requiring precise control under load.

HYBRID Propelling NOZZLE by VICUSdt

The Hybrid Nozzle developed by VICUSdt is a cutting-edge propulsion solution that enhances efficiency through the use of innovative materials and state-of-the-art manufacturing.

Featuring a stainless steel structural frame combined with a lightweight epoxy resin hydrodynamic profile, the nozzle achieves exceptional performance with a significantly lower weight than conventional steel nozzles.

Suitable for all vessel types—from workboats to pleasure craft and fishing vessels—the Hybrid Nozzle delivers improved thrust and fuel efficiency without compromising structural integrity or durability.

KEY ADVANTAGES of our hybrid propeller nozzle

- CORROSION FREE: No anodes needed – zero added drag or maintenance.

- SEAMLESS DESIGN: No external welds, ensuring smooth flow.

- LIGHTWEIGHT: Over 60% lighter than traditional steel nozzles.

- HIGH PRECISION: Tight manufacturing tolerances for consistent performance.

- STANDARD OR CFD-OPTIMIZED PROFILE

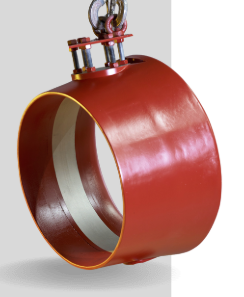

Inside a 3.38m Propeller Nozzle for a Stern Trawler

At VICUSdt, we specialize in the design and manufacturing of propeller nozzles that combine advanced hydrodynamic performance with robust shipyard adaptability.

A recent project involved a 3.38m diameter propeller nozzle in carbon steel, developed for the retrofitting of a stern trawler. After completing sandblasting and primer coating, the nozzle was ready for shipment to the shipyard for installation.

Some key features of this nozzle include:

- Loose brackets and plates for easy cutting and fitting on site during dry dock.

- Round bars fitted in both leading and trailing edges, typical of 19A nozzles, also applied to the brackets.

- Submerged arc welding ensuring watertightness, durability, and a perfect finish, with semi-automated precision.

- Custom keel connection box, designed for the vessel’s closed stern, allowing proper adjustment forward and aft.

This project highlights our ability to combine advanced engineering with practical shipyard needs, delivering robust and efficient nozzles that enhance vessel performance and durability.