At VICUSdt, we specialize in CPP retrofit solutions tailored to trawlers operating in demanding environments. Our controllable pitch propellers for trawlers improve propulsion efficiency, reduce vibration and cavitation, and adapt to different loading conditions. In this case study, we present a successful CPP upgrade on a Peruvian fishing fleet, enhancing vessel performance with CFD optimization and custom blade design. This case study showcases the complete CPP retrofit process for trawlers, highlighting our advanced use of CFD and propeller optimization to meet demanding operational profiles.

Customer: Pescanova, Deris, TASA, Iberconsa, Inpesca

Related services: Ship resistance & powering prediction, CFD simulation, adapted propeller design & supply

Scope of work

- 3D model of the hull

- Core and base measurements for current CPP

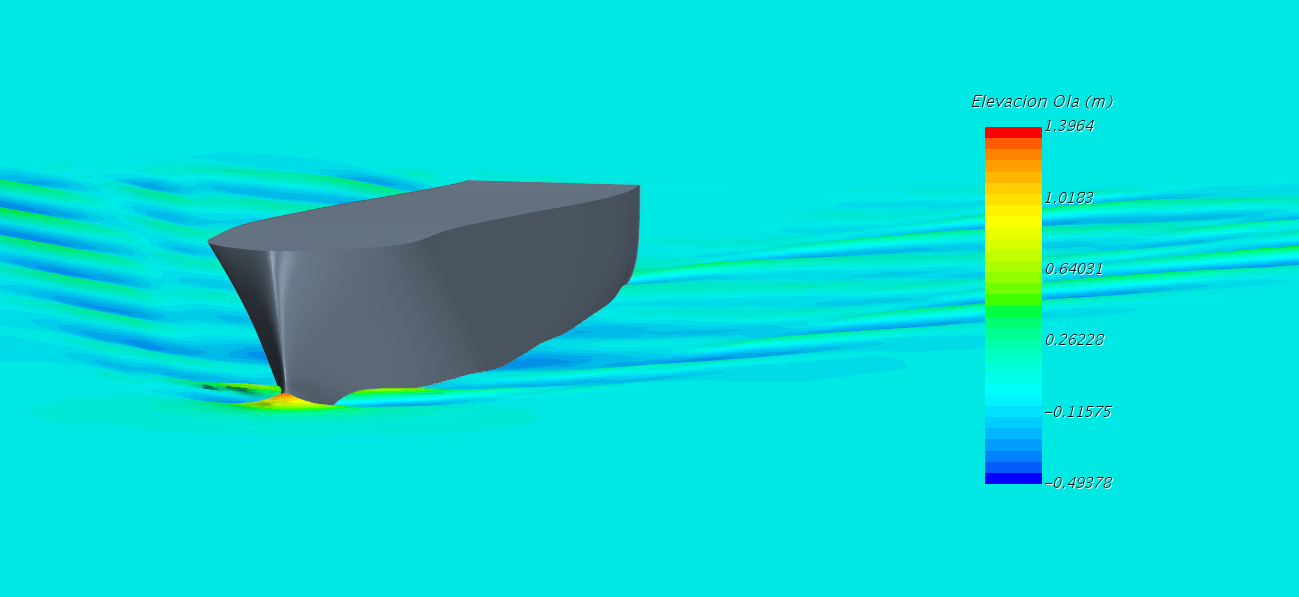

- Hull analysis by CFD tools

- Nominal wake calculation

- Self-propulsion computation in conditions of drag and free running

- Cavitation analysis

- Propeller geometry design, adapted to vessel operational profile

- Supply of blades compatible with the CPP core

VICUSdt performed a controllable-pitch propeller (CPP) retrofit on trawlers of a Peruvian fishing fleet. The project included scanning the existing propeller, generating a wake-aligned blade geometry using CFD, fabricating new CPP blades, and supervising installation at the shipyard. This retrofit led to enhanced propulsion efficiency and maneuverability, fitting the vessels’ operational profile.

CPP Blade Evaluation & Optimization for Trawlers

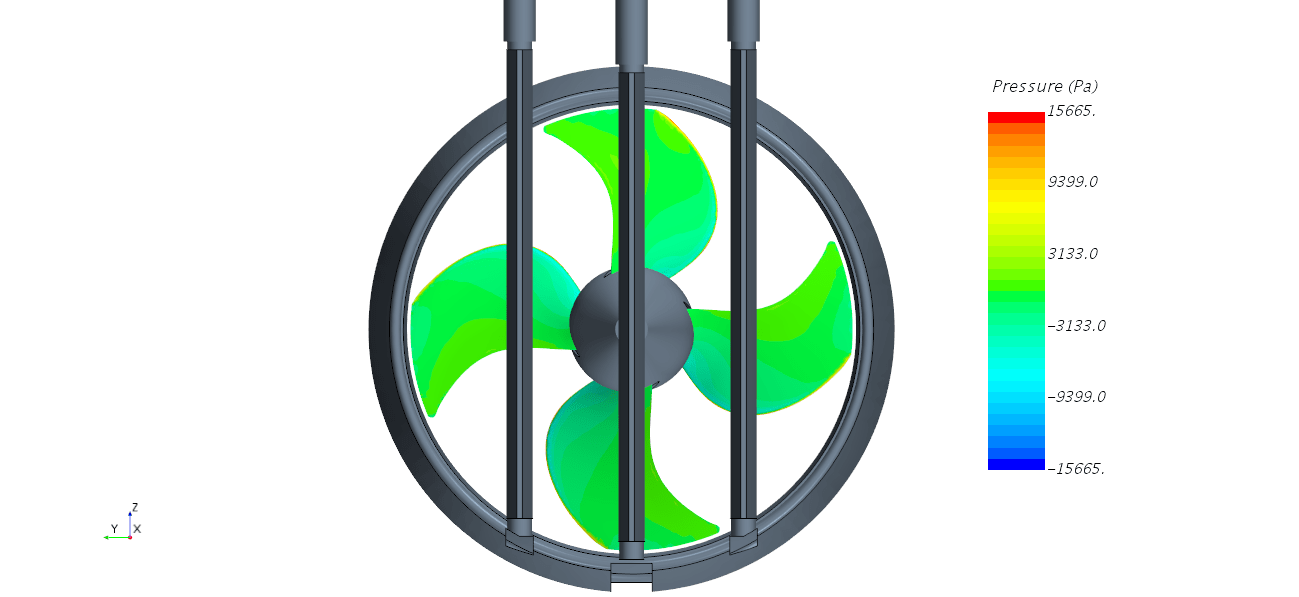

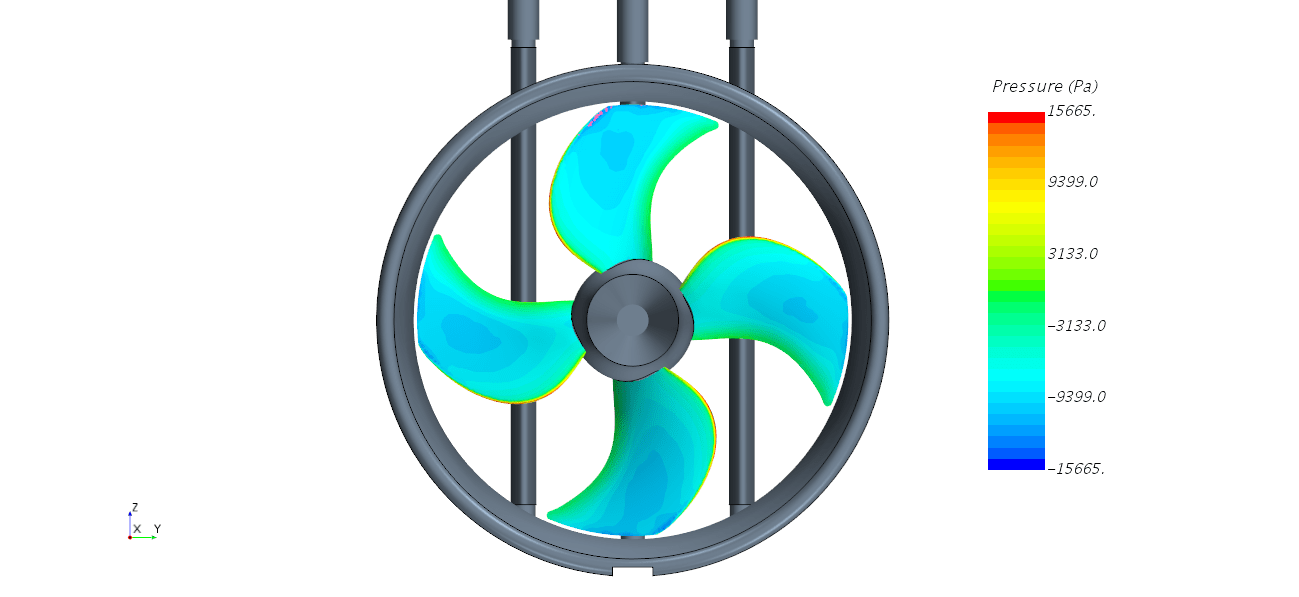

Optimizing controllable pitch propellers for trawlers requires a precise understanding of the vessel’s operational profile, including varying loads, sea conditions, and propulsion modes. At VICUSdt, we begin every CPP retrofit project with a thorough analysis of the existing blade geometry and cavitation behavior.

The evaluation of CPP blades offers a unique opportunity to enhance propulsion efficiency and reduce vibration and erosion-related damage. For trawlers, blade redesign poses additional challenges, as the vessel must operate under both full load and lightly loaded conditions, depending on its route and fishing activity.

In this case, the original CPP was analyzed using CFD (Computational Fluid Dynamics), allowing us to identify critical areas of improvement. The resulting CPP optimization led to a significant increase in overall performance, enhancing the vessel’s maneuverability and reducing fuel consumption.

Thanks to our adapted design, we achieved improvements of 5% compared to the original equipment. and reduced the risk of cavitation. By refining the blade profile to better suit trawling operations, we also contributed to longer equipment lifespan and better onboard comfort.

Throughout the process, our engineers focused on minimizing vibration, especially under variable pitch settings, a common scenario in the control pitch propeller system of fishing vessels.

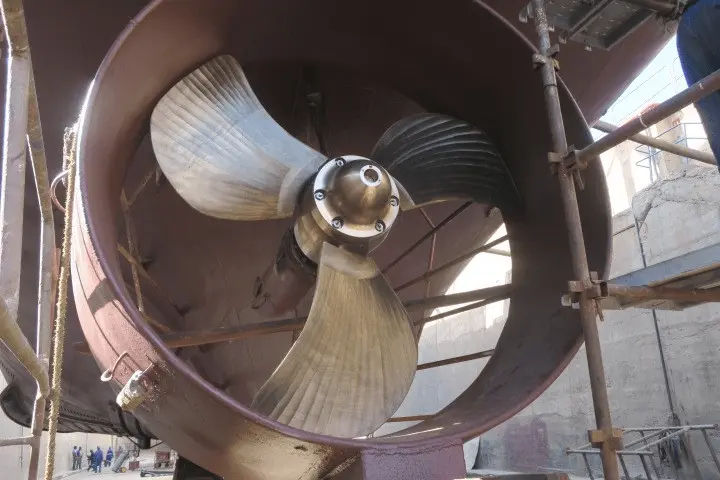

CPP Retrofit Installation & Performance Gains on Trawlers

Our CPP retrofit for trawlers ensures full compatibility with existing systems, reducing downtime and enhancing operational efficiency. Fot that, a VICUSdt technician traveled to the shipyard, to made an exhaustive measurement of the base of the blade and checked gaps in the equipment. In this way, we achieved that the lace of the blades in the original core was perfect.

The base of the new blades, which can be manufactured in Cu3 bronze or stainless steel, is adaptable to any type of core. As a reference, we have already made substitutions in Kamewa, MAN, LIPS, SILLA and Wichmann equipment, among other brands.

Contact us for a retrofit solutionWhy Choose VICUSdt for CPP Retrofit Projects

With years of experience optimizing control pitch propeller systems, VICUSdt delivers tailor-made solutions for trawlers. Our advanced CFD tools, propeller shaft design expertise, and close collaboration with shipyards guarantee efficient and long-lasting results. From blade redesign to installation, we cover the full CPP lifecycle.