Customer: Copeinca, Tasa

Related services: Ship resistance & powering prediction, CFD simulation, adapted propeller design & supply

Scope of work

- Express audit:

- Study of hydrodynamic improvements applicable to the vessel

- Statistical prediction of the impact of improvements

- Economic return on investment

- 3D model of the hull

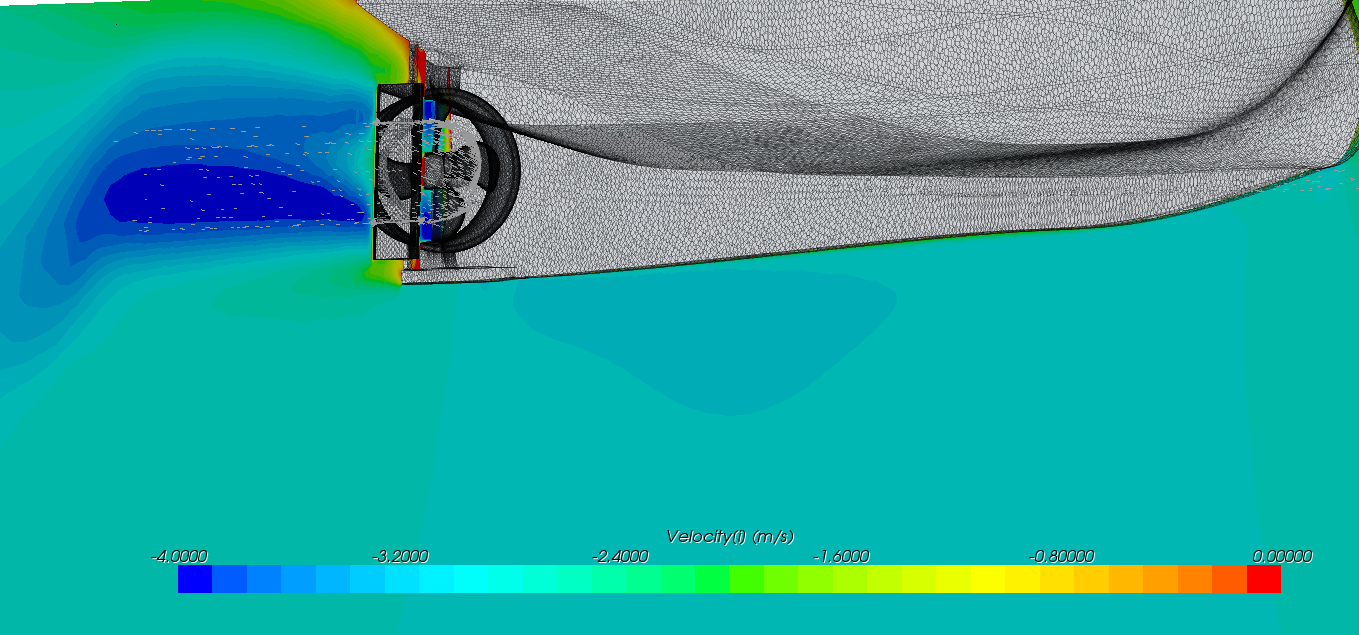

- Hull analysis by CFD tools

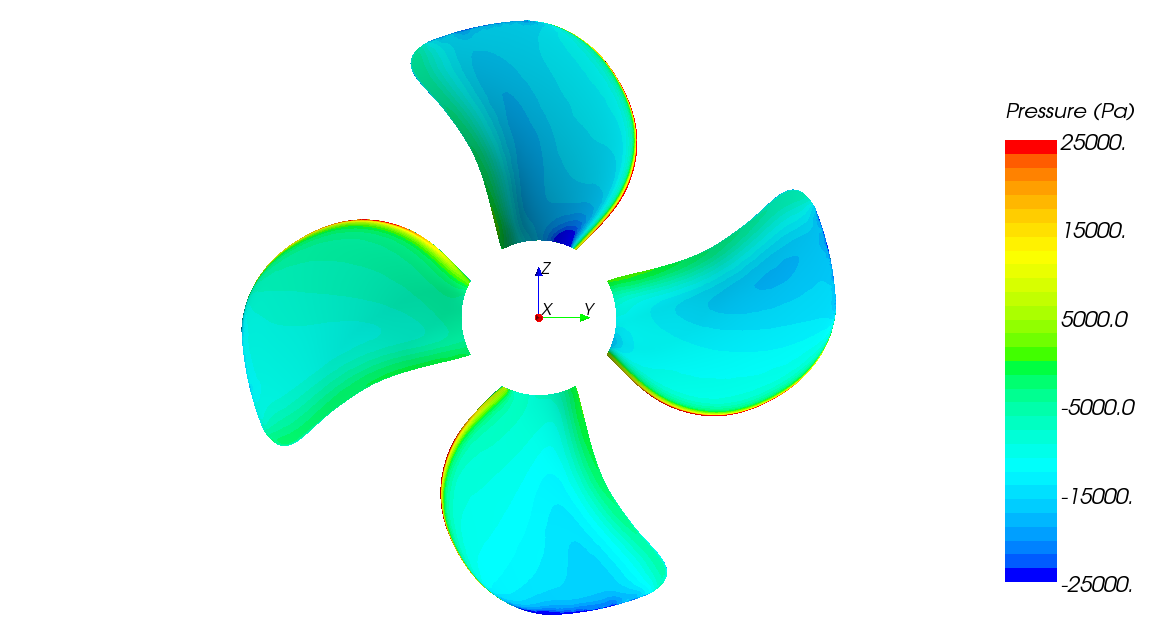

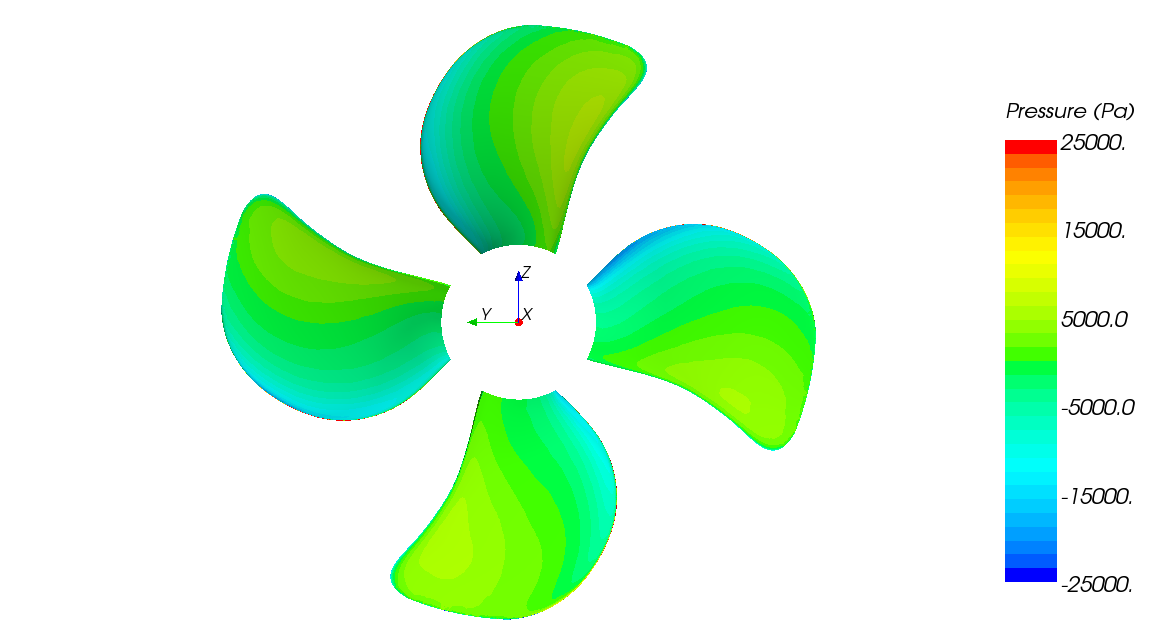

- Nominal wake calculation

- Self-propulsion computation

- Propeller geometry design, adapted to vessel operational profile

- Supply of blades compatible with the CPP core

- Supply of adapted rudder designed in conjunction with the propeller

VICUSdt conducted a propeller repair for seiners by retrofitting controllable-pitch propeller (CPP) blades and a wake-adapted rudder on fishing vessels owned by Copeinca/Tasa in Peru. Using CFD wake and powering analysis, tailored propeller geometry was created to match real operational profiles. The retrofit delivered approximately 4% improved propulsion efficiency and enhanced maneuverability. A VICUSdt technician oversaw installation at the shipyard, ensuring alignment with hydrodynamic objectives and mechanical execution.

CPP Retrofit on Seiners: Process & Analysis

The CPP retrofit seiners project followed VICUSdt’s two-phase methodology: an Express Audit and implementation. The audit included hull modeling, wake and resistance prediction, and self-propulsion CFD simulations to define optimal CPP geometry. Copeinca owned seiners operate at variable loads: towing both fishing nets and transit. CFD allowed pitch and blade shape to be adapted to these conditions, ensuring efficient thrust across operational range.

Following blade design, the retrofit included supply of compatible CPP blades and a bespoke rudder shaped to recover propeller energy and refine handling. A VICUSdt naval engineer supervised mechanical fitting at the Peruvian shipyard to guarantee accuracy. The result was a 4% gain in propulsion performance, without modifying bow geometry.

Contact us to upgrade your fishing vessel propulsion