Customer: Heimli Ship Design

Related services: ship resistance & powering prediction; hull form optimization

Scope of work:

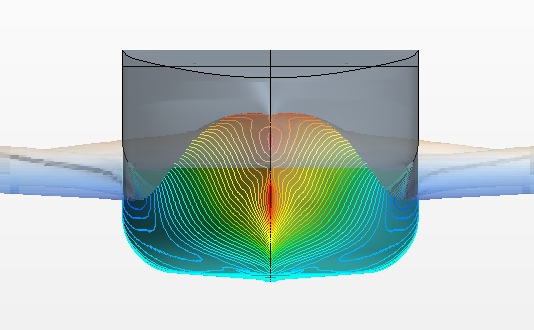

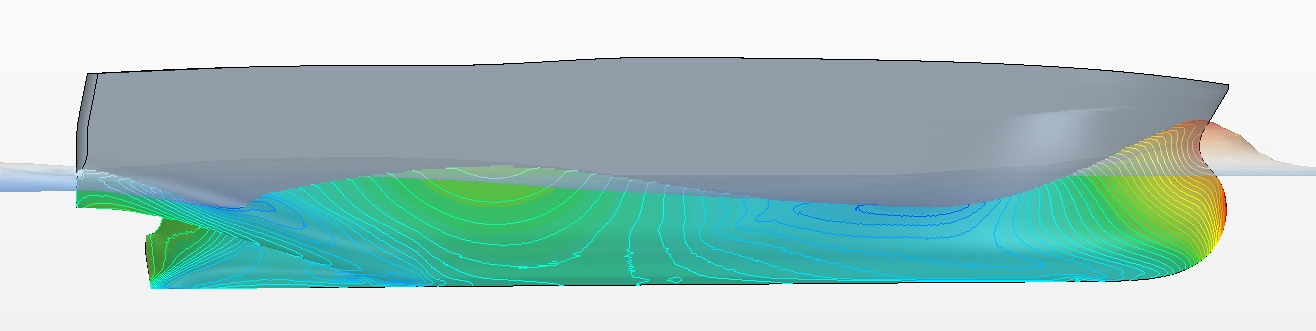

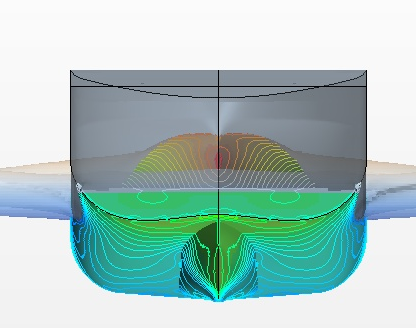

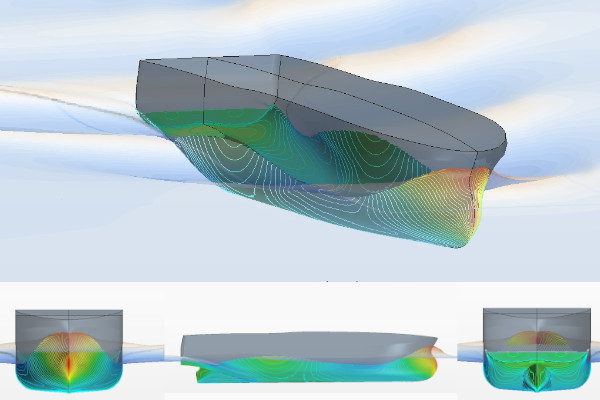

Powering prediction, hull streamlines and wakefiled calculation using viscous CFD code. The resistance values were postprocessed using NavCad to make a comprehensive analysis of ship performance. Furthermore, we carried out a CFD calculation of nominal wakefield, the velocity field in front of the propeller was supplied to the propeller designer for a wake adapted propeller design.

This case presents how VICUSdt’s ship resistance and wake CFD analysis helped predict and optimize vessel performance ahead of physical trials. By applying CFD simulations on hull resistance and wake flow, our team validated powering requirements and informed propulsion package design. The results enabled improved speed prediction, reduced cavitation risk, and efficient thrust allocation—helping naval architects and shipyards avoid costly iterations and ensure delivery of contract performance.

CFD-Based Resistance & Wake Flow Modelling

Through ship resistance and wake CFD analysis, VICUSdt reconstructed 3D hull geometry and executed simulations across various drafts and speeds. The analysis provided detailed resistance breakdown—friction, wave-making and form components—and visualized wake velocity deficits downstream. This information guided propeller design and nozzle placement to align thrust with slipstream properties. Wake flow mapping allowed assessment of propeller inflow uniformity, while resistance data facilitated accurate powering predictions essential for fuel consumption modeling. With results verified against empirical and tank data, designers received validated performance metrics before vessel construction and trials.

Benefits for Ship Design & Performance Prediction

Accurate ship resistance and wake CFD analysis delivers key advantages to ship designers, naval architects, and shipyards:

-

Reliable powering forecasts: Knowing precise resistance values under different loading conditions ensures propulsion systems meet speed targets without overdesign.

-

Optimized propulsion layout: Wake alignment with propeller geometry and rudder positioning enhances fuel efficiency and reduces cavitation.

-

Reduced trial risk: Early detection of performance shortfalls avoids costly post-delivery modifications and sea-trial failures.

-

Design iteration speed: CFD enables rapid comparison of hull or appendage variants, supporting informed decision-making during concept and model stages.

-

Environmental compliance: Reduced resistance translates into lower fuel usage and emissions—supporting EEDI, EEXI, and CII objectives.

This CFD-driven proactive approach ensures ships are built right the first time, with performance promises delivered in reality.

VICUSdt has cooperated in several projects with Heimli Ship Design, ensuring a good performance of its designs. A correct prediction, using CFD tools, is the first step to a successful project.

Ship´s data:

TAUPO

Length 43 m. Width 11 m.

Speed 13 knots.

Brt: 650 tons.

Capacity: 320 tons of fish.

This vessel has being built by FMV AS for Napier AS.

Contact us to optimize hull performance