ACCOMODATION VESSEL HULL FORM OPTIMIZATION, WAKE CALCULATION, POWERING PREDICTION, SHIP PERFORMANCE SIMULATION, SEAKEEPING AND DP ANALYSIS Customer: H.J. BARRERAS SHIPYARD Related services: CFD SIMULATION SHIPS, SHIP PERFORMANCE, DESIGN Scope of work:

- Data collection

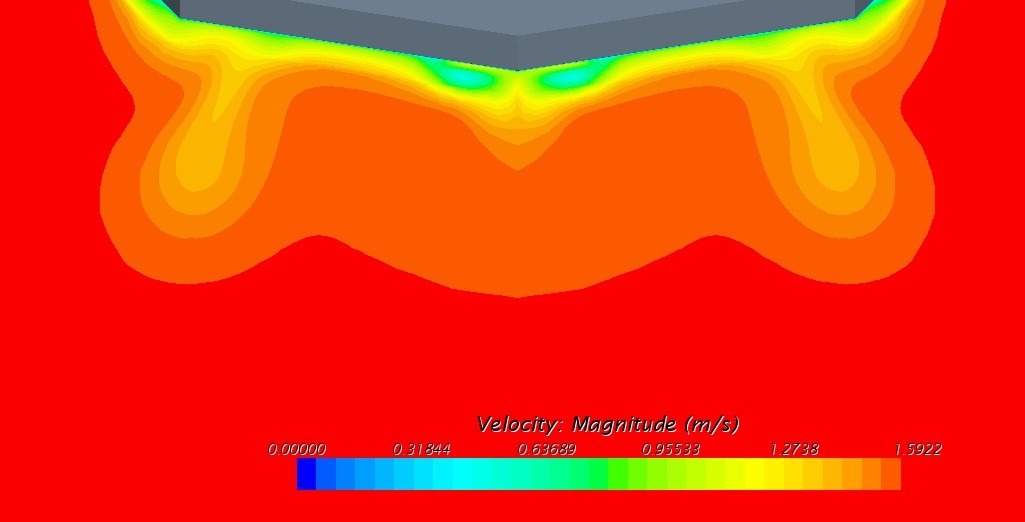

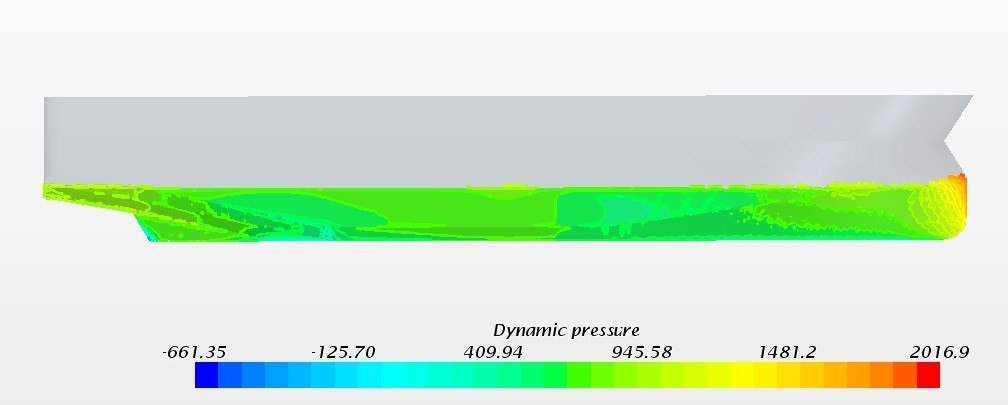

- Ship resistance and power prediction with CFD for different speeds and loading conditions

- Dynamic trim analysis

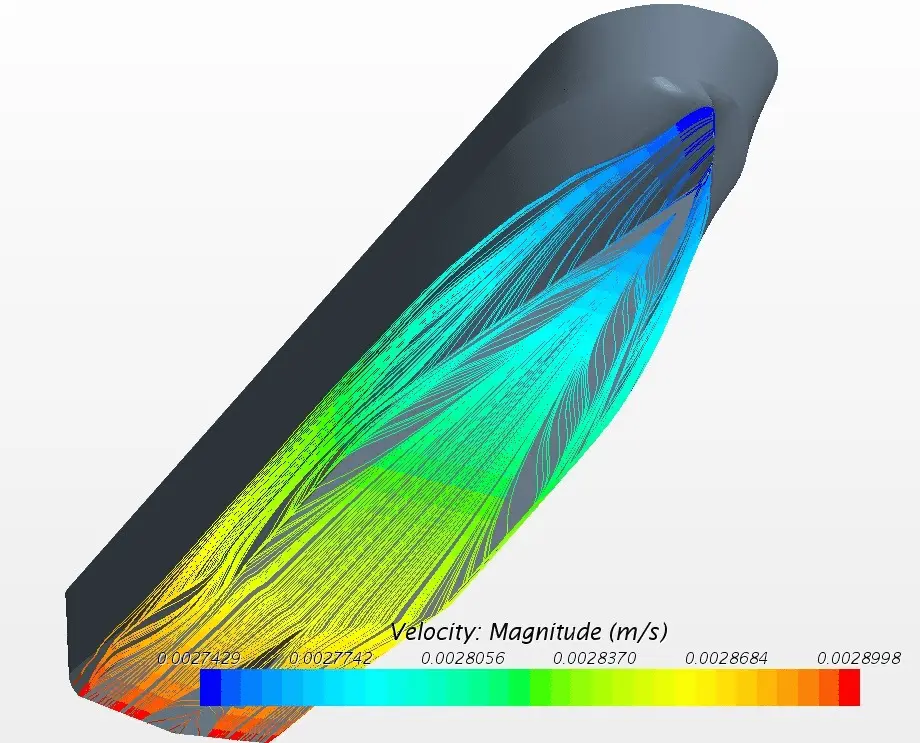

- Wake calculation

- Streamlines analysis

- Optimization of hull

o Skeg design o Appendages design and alignment (PODs headboxes) o Stern shape o Tunnel thrusters openings

- Sea keeping analysis

o RAOs o Accelerations

- DP analysis

o Environmental forces calculations with CFD (wind, waves and current) o Thruster-thruster interaction and hull-thruster interaction for thrust deduction identification o DP capability plot and ERN

- Ship performance simulation

o Fuel consumption calculation with SHIPERTOOLS in DP operation Results: As a result of this project, it was obtained a new optimized hull with a new skeg designed which lead into a resistance reduction of 10.8% in free sailing condition at design speed. Due to the advance stage of building other options studied could not be implemented but a rounded shape (free of knuckles) was proposed to the Shipyard. This modification lead to an additional 10% savings in hull resistance at design speed. Tunnel thrusters openings were studied in terms of added resistance and performance for DP operation. Different openings were designed and studied with CFD, so the ones finally chosen represented a resistance reduction of 0.75% compared to the original cases (tunnels with no fairing). When it comes to DP performance, they showed an increase of 5.6% in thrust compared to the original case. PODs vertical position was studied for optimum thrust in DP operation and headboxes were designed for minimum resistance. A complete Seakeeping study was performed including Heave, Pitch and Roll RAOs and accelerations in different locations such as DP room or emergency bridge. In terms of Seakeeping performance, different sterns were designed and studied in different wave condtions obtaining as result, for the best one, impact forces reduction in the stern around 6%. A complete DP capability analysis was performed in two stages. First one, a preliminary plot with environmental forces obtained from coefficients scaling from similar projects and a second one, where environmental loads (wind, waves and current) were calculated by means of CFD in order to give an accurate and realistic DP capability plot. Thruster-thruster interaction and hull-thruster interaction was studied as well, so thrust in each condition could be calculated accurately. ERN was also provided to shipyard for ship classification according to DnV regulations. Ship performance operation under DP condition was simulated with own custom made performance simulator SHIPERTOOLS to assure daily fuel consumption as per contract requirements.