Propulsion equipment

We’ll be pleased to answer your questions

Engine performance monitoring: Revolutionising maritime diagnostics

The Doctor: Intelligent engine monitoring and diagnostic solution

Fuchs Technology introduces an innovative range of high-precision, online multi-cylinder engine performance monitoring systems, designed for both portable and fixed installations onboard. Engine Performance Monitoring is essential for achieving savings in engine maintenance and operation. By ensuring a properly balanced engine in real-time, significant reductions in spare parts expenses and fuel consumption are attainable, as evidenced by rigorous measurements.

This ultimate tool for engine performance monitoring offers an online, reliable platform for real-time engine diagnostics, accessible from any laptop or the Superintendent’s computer at the office.

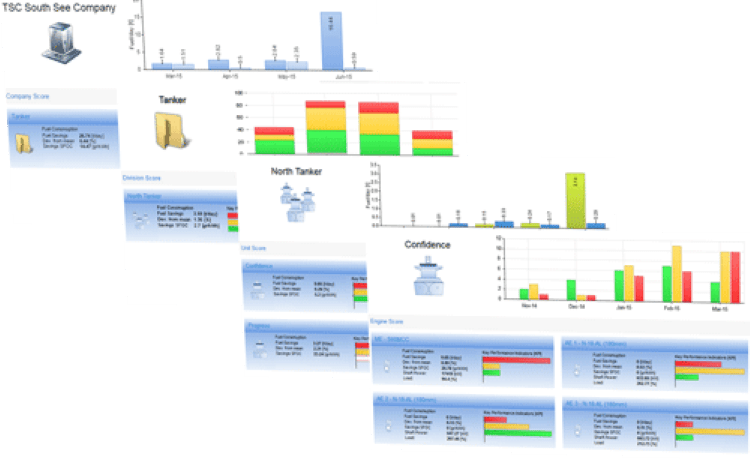

EDCenter: Cloud-Based Engine Diagnostic Excellence

The EDCenter is a cutting-edge engine diagnostic cloud application that analyses and diagnoses engine conditions across the entire fleet based on various parameters. It predicts incipient failures, continuously monitors fuel consumption, and identifies potential savings. This powerful multi-user system transforms the process of data collection and analysis, facilitating immediate action by chiefs, superintendents, fleet managers, and external experts through automatic email alerts. This ensures optimal energy efficiency and minimised maintenance costs.

DocSoft E3: The heart of ship-level engine monitoring

DocSoft E3 serves as the core of ship or power plant-level engine performance monitoring, capturing and evaluating all engine parameters online. This system not only predicts incipient failures but also integrates with the ship’s alarm system for comprehensive monitoring. By sending engine data to the EDCenter, it ensures that onshore managers are promptly informed of any abnormalities, enabling swift action to maintain energy efficiency and reduce maintenance costs.

DocPad 1/2 e-600 e-line: Pioneering tablet-based engine analysis

The DocPad e-603 / DocPad2 e-623 starts a new era of tablet-based engine analysis systems. The new portable single cylinder monitoring system consists of a data acquisition unit in combination with a modern tablet PC. The system is part of the newly launched “e-line” family, which includes a complete solution from data capturing with an automatic engine report as well as an automatic engine analysis software (see DocSoft e-3). In the unique and cloud-based engine diagnostic center , called “EDCenter”, the data is automatically analyzed and compiled to a fleet overview.

The combination of the tablet technology allows the system to connect directly to the Internet and sends the engine reports to the EDCenter in order to update the fleet performance. On various engine parameters the EDCenter shows the engine condition with traffic lights and indicates when savings can be achieved.

The DocPad2 represents the new generation of this portable single monitoring device and distinguishes itself through a higher resolution (0.05 degree crank angle) and therefore higher accuracy.

DocGate 732 e-line: Robust and cost-effective monitoring

The DocGate e-732 is a cost effective and robust permanent multi-channel online data acquisition and alarm device. The system does not require a computer in the engine room. It is online connected via Ethernet with a remote workstation in the control room. The system runs with the powerful DocSoft e-3 analysis software which controls the engine permanently. It includes alarm detection with visual and acoustic alarm indication.

The DocGate e-732 is designed for permanent 24/7 installation in rough and harsh engine room environments. The system can be equipped with a wireless and ergonomic tablet PC to operate around the engine.

The system is part of a new overall solution concept called “e-line”. This solution automates the huge data workflow between ship and operator. Engine data can be accessed at any time in order to keep track of the history and predict what will happen with the engine condition in the future.

DocHub 932 e-line: Portable multi-channel data acquisition

The DocHub e-932 is a new portable multi-channel online data acquisition device which is controlled wirelessly by an ergonomic tablet PC. The system runs with the powerful DocSoft e-3 analysis software. The technology allows a wireless connection to the control room workstation.

The DocHub e-932 is part of a new overall solution concept called “e-line“. This solution automates the huge workflow between ship and operator. Engine data can be accessed at any time in order to keep track of the history and predict what will happen with the engine condition in the future.

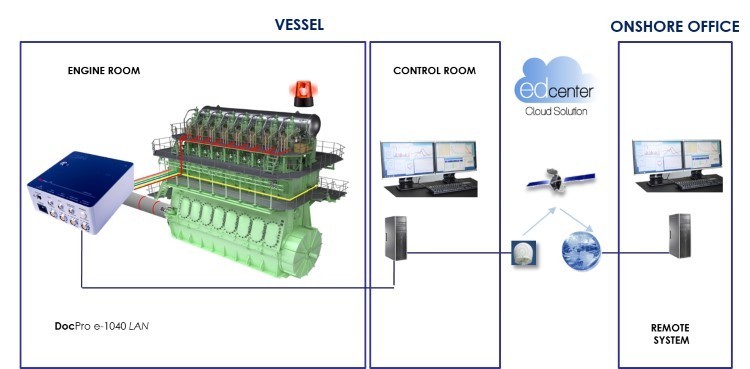

DocPro 1040 e-line: Advanced engine data acquisition system

The DocPro e-1040 is a robust multi-channel online data acquisition system for permanent and continuous engine data acquisition. Compared to the DocGate e-732, the system is additionally able to simultaneously evaluate the shaft power. This unique system is able to online compare the current measurements with the shoptest data stored in the DocSoft e-3.

The DocPro is online connected via Ethernet with a remote workstation in the control room. The system runs with the powerful DocSoft e-3 analysis software which controls the engine permanently based on the key performance indicators. Therefore, the system also includes alarm detection with visual and acoustic alarm indication.

The DocPro is designed for permanent 24/7 installations in rough and harsh engine room environments. Additionally, the system can be equipped with a wireless and ergonomic tablet PC to operate flexibly around the engine.

The system is part of a new overall solution concept called “e-line“. This solution automates the huge data workflow between ship and operator. Engine data can be accessed at any time to keep track of the history and predict what will happen with the engine condition in the future.